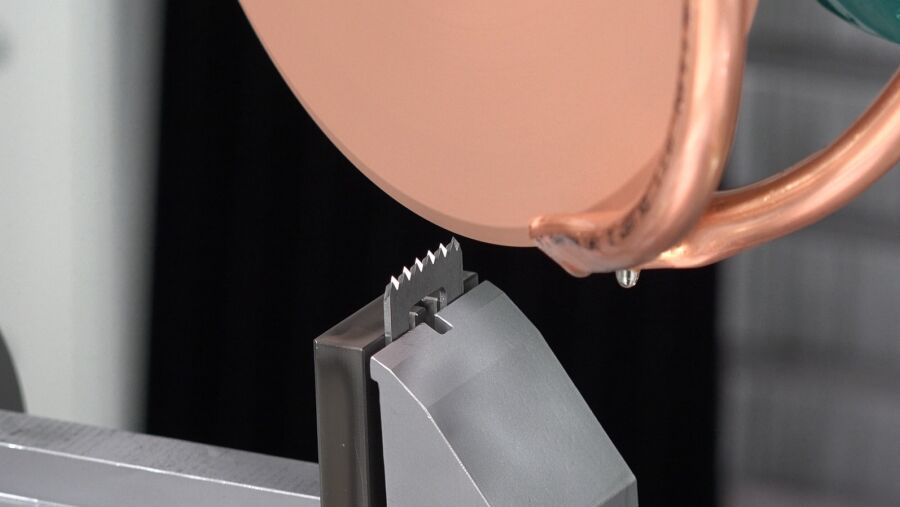

Bone Saw Designed in Qg1, Ground on a SCHNEEBERGER Norma NGC

For many grinding applications, the medical industry relies on SCHNEEBERGER software and 5-axes CNC machines. The CAD/CAM software Qg1 offers both: 3D STEP-model import as well as parameter-based programming of various tools like bone saws, hip rasps, dental drills and instruments.

Bone Saw Production on SCHNEEBERGER CNC tool grinder Norma NGC

Each tool family includes a set of pre-programmed parts in SCHNEEBERGER’s data base Toogle. These tools are tested and approved by medical professionals. The production of medical equipment is hereby much easier than the tasks that await them in a hospital or dental clinic.

A Norma NGC produces bone saws effortlessly and with an autonomy of 270 pieces. Find out more on www.schneeberger.swiss or ask your nearest sales representative.

News overview

Categories

All posts

- Fresh & Sharp in Quinto Qg1, release 2025-04

- Fresh & Sharp in Quinto Qg1, release 2024-09

- SCHNEEBERGER once again climbs the Mount Everest of grinding: Carbide Power Skiving Cutter Module 0.17 in the highest precision class

- The American Metalworking Community met at IMTS 2024; where SCHNEEBERGER presented the latest trends in CNC grinding technology

- IWF Atlanta 2024: Corrugated Knives, Woodworking Inserts and more with Qg1 and SCHNEEBERGER