Brighetti Meccanica – Manufacturer of high-precision broaches and a pioneer in digitalized production planning

Near Bologna Italy, BRIGHETTI MECCANICA manufactures broaches, for multi edge-, profile and special flutes, and among others, broaching tools for Torx wrenches. For their fully automated production (using Industry 4.0) they rely on SCHNEEBERGER technology.

"We decided to order a second Gemini NGM after our positive experience with the first one," says Dr. Negrisoli, owner of the company. And the second Gemini has arrived, this time complete with robot tool loading and laser marking. "It is with great satisfaction to walk through the workshop and see that our production is fully automated," adds Dr. Negrisoli, "also because scrap is practically zero. The work cycle, in fact, includes:

- Preparation of the production batch at a workstation in the technical office. The machine is also integrated into the digital image of the factory layout according to specifications entered in Industry 4.0.

- At the machine the operator starts the next production job.

- With each piece produced, the Gemini checks the main dimensions and continues as long as they are within tolerance. If not, it intervenes and automatically corrects the parameters to keep the product within the required tolerance. Luca the machine operator proudly states, the Gemini NGM produces repeatably and continuously with deviations well below 1/100 (0.0004“) of a millimeter.

- The finished part is removed by the robot, air cleaned and laser marked before deposited into the correct pallet.

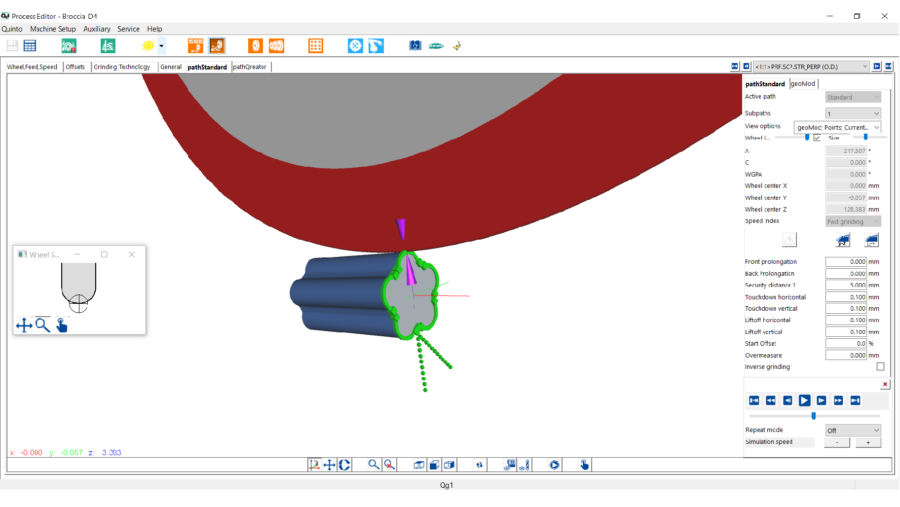

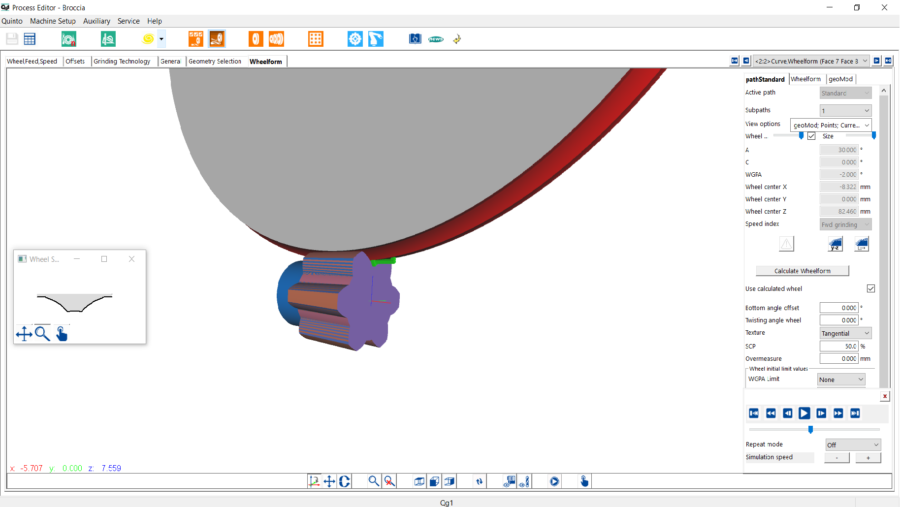

As for the new Qg1 software, according to machine operator Andrei Rinca, a real leap in quality has been achieved, especially thanks to the STEP interface. The technical department creates 3D models of the workpiece, these are imported into the SCHNEEBERGER software, which returns a simulated grinding cycle in just a few steps. The result can be immediately executed on the machine.

Great importance is also paid to the digitalization of production at BRIGHETTI MECCANICA. Dr. Negrisoli is proud of his automated inventories, which together with the machines are integrated into Industry 4.0. This makes it possible, among other things, to retrieve production statistics or prepare quotations with precise prices, knowing the cycle times in advance.

"I see our future together with SCHNEEBERGER," says Dr. Negrisoli, "not only because their machines and software meet all our technical requirements, but also because of the relationship and trust we have in the Italian subsidiary. Competent technicians are always quickly at our side and on time with their SCHNEEBERGER Rapid Support hotline."

For

SCHNEEBERGER, the close cooperation with the dynamic and technology-savvy

company BRIGHETTI MECCANICA is highly gratifying.

Michele Dell'Eva, J. SCHNEEBERGER Service Italia srl

Categories

All posts

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- Reading tip: FORUM article on automation solutions for modern CNC grinding machines

- BRIANI and SCHNEEBERGER, a 30-year exemplary Collaboration for the Italian Tool Industry

- CCTV Business Report about Magally Technology reaches Millions of Viewers

- Turning the tides by going full CNC and automation in carbide insert production