Live from EMO, Day 1: The ultra-compact Aries NGP SCARA reliably grinds ceramic cutting tools from solid.

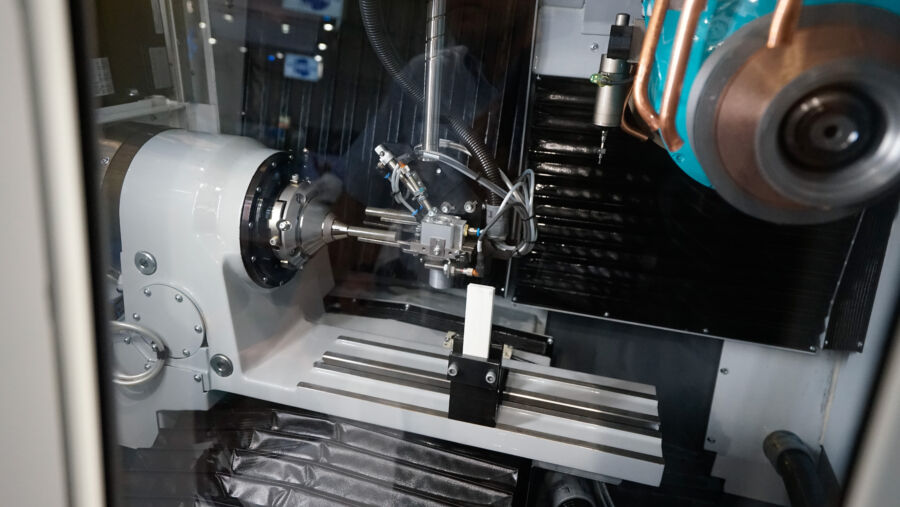

The 5-axis CNC grinding machine Aries NGP from SCHNEEBERGER, equipped with an agile Fanuc SCARA robot, produces high-precision tools made of high-tech cutting ceramics from CeramTec. Ø12mm high-performance cutters and drills are ground on 3.5m² footprint.

Designed for tool production, the Aries NGP is equipped with a FANUC SCARA robot, integrated oil filtration and temperature control. All this, requireing less than 3.5 m² of floor space. The 4-axis horizontal robot is the first choice in terms of speed (6.5 seconds) and repeatability. With impressive ease and precision, the ultra-compact Aries NGP cuts high-tech cutting ceramics and proves that it is in no way inferior to its larger sister models in terms of precision.

The Qg1 CAD/CAM grinding software allows quick and easy programming of the tools. Thanks to the immense database Toogle, the machine is ready for production after a few clicks.

The cutting ceramic silicon aluminum oxide nitride, SiAlON for short, from the CeramTec company is used as the material. SiAlON is characterized in particular by its hard and wear-resistant surface and extremely fracture-resistant core. The optimum balance between toughness and wear resistance enables high cutting parameters during roughing. The material properties can be adjusted according to the main application of the cutting task. In particular, the cutting ceramic shows its advantages over carbide in the machining of Inconel and nickel alloys, which are mainly used in the aerospace and energy and gas industries.

Are you interested in the automated production of tools? Don't miss EMO Hannover 2023; the specialists from SCHNEEBERGER will be happy to advise you.

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.