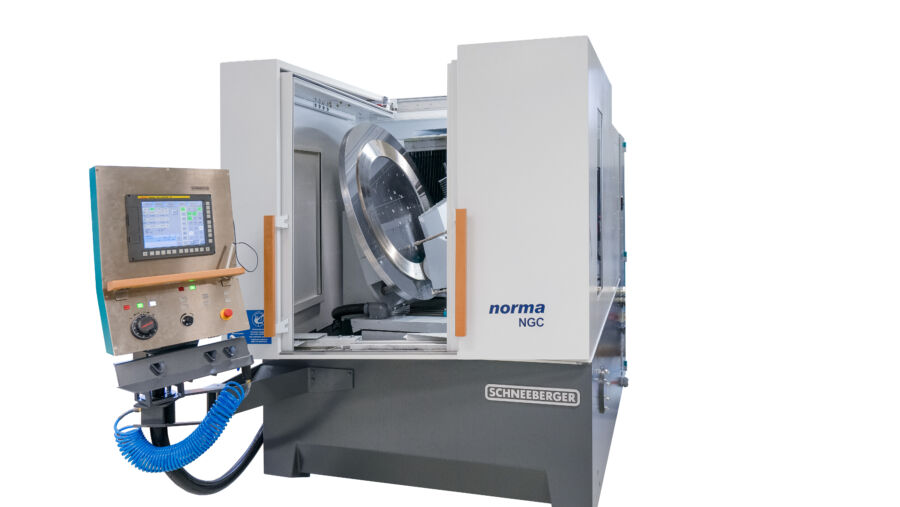

Norma pulverizes your conventional production with the special edition Pulverizing Disc grinder NGC-LD

With CNC-ground pulverizing disks, nothing stands in the way of processing plastics (thermoplast, duroplast, elastomer) and various chemical products. The third generation of the globally popular SCHNEEBERGER grinding machine scores with higher grinding spindle performance, optimized structural mechanics and sophisticated grinding processes. New for pulverizing disks up to 1’000 mm diameter.

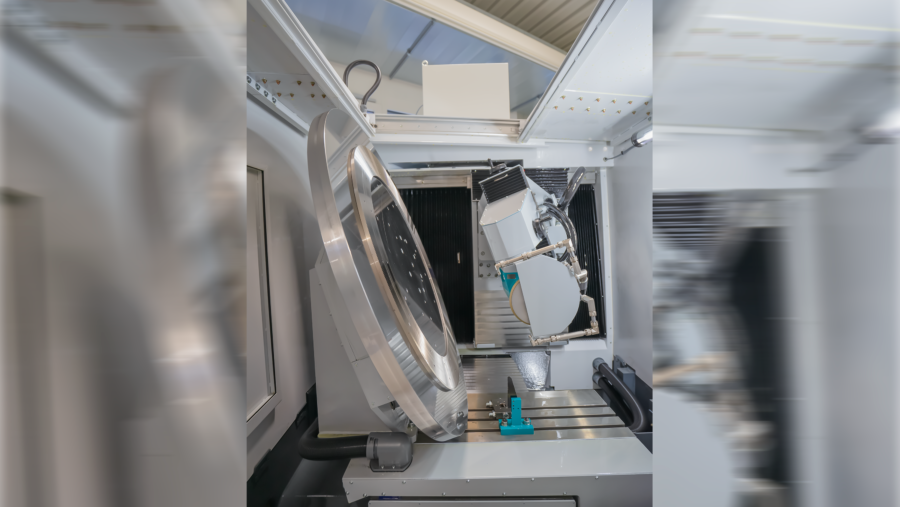

Grinding of a pulverising disk on Norma NGC-LD

The user-friendly software allows for the definition of pitch, concave angle, cutting angle, number of teeth, dressing intervals and infeed. All known tooth geometries (Pallmann, Reduction Engineering, Orenda, Neue Herbold, Zerma, Global Cutting Systems, Avalong, PK, Wedco and many more) are easily and quickly programmed and ground this way.

Pulverizing disks with a diameter of up to 1’000 mm place special demands on the machine concept. The CNC grinding machine Norma NGC-LD (large disc) has a 30° inclined dividing head and grinding head which guarantees an optimal machining process for all common disks. This allows in precise and efficient grinding results, coupled with generous accessibility when loading the grinding wheels. An optional available dressing unit allows for the conditioning of the grinding wheel inside the machine.

Machine specifications and further information can be viewed under the following link.

Is grinding pulverizing disk your business? Or shall it become one? Your local SCHNEEBERGER consultant will be happy to help with further details.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability