Profiling of Power Skiving Cutter in seven steps

The right grinding strategy is key for skiving cutter profiling. The SCHNEEBERGER application experts provide an initial insight using the example of a power skiving cutter, HSS, Ø 108.5 mm, L 19 mm, Z35.

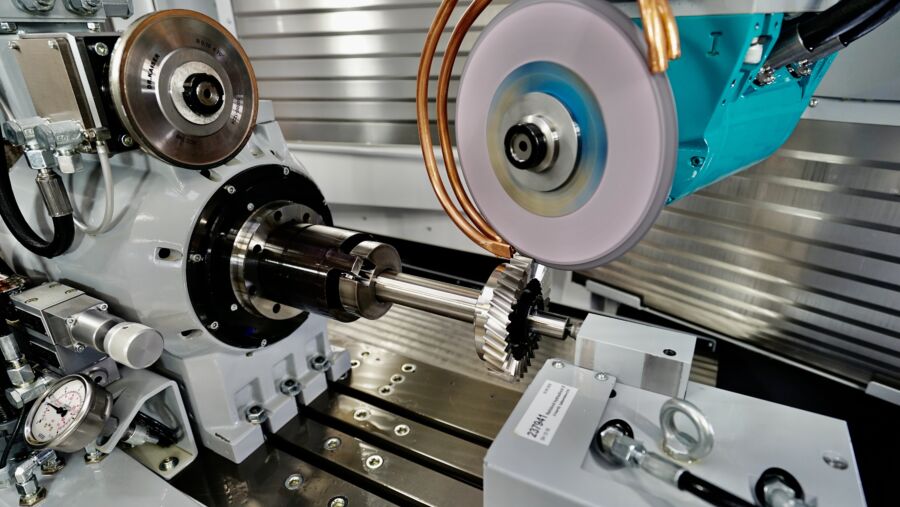

Profiling of Power Skiving Cutter on SCHNEEBERGER Gemini NGM

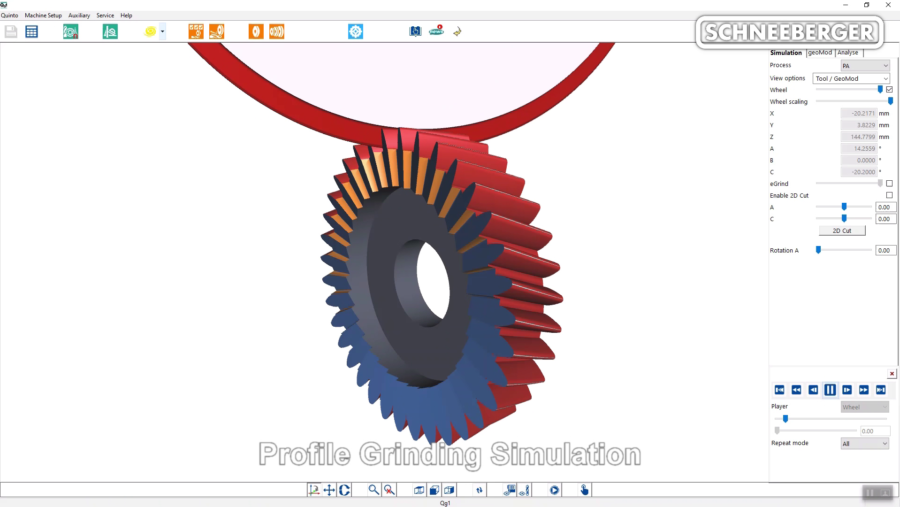

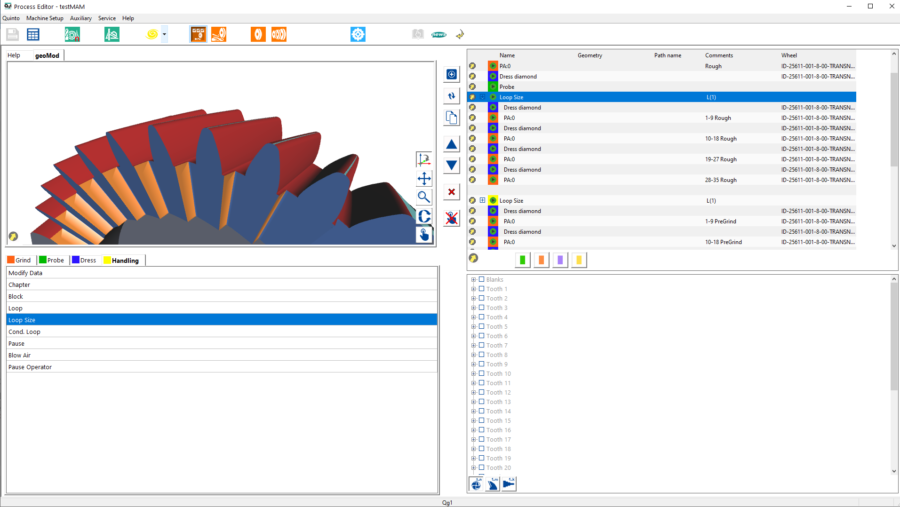

The power skiving cutter grinding process is divided into 3 sub-processes; roughing, pre-grinding and finish grinding with spark out. The blank, which is pre-milled depending on the module size, is ground to a radial oversize of 0.08 mm in the roughing process. One flank of the power skiving cutter is ground with six passes, and dressed after every 9 teeth. Pre-grinding is done with 0.04 mm radial oversize. Each flank is now ground with 15 passes, the grinding wheel is periodically dressed after 9 teeth. The continuous start option shifts the starting tooth by 11 teeth at a time. Therefore the newly dressed wheel starts at a different tooth position each time.

Before the final grinding, the grinding wheel is dressed one last time with a higher overlap ratio. Two passes with 0.02 mm infeed each follow, 30 strokes per flank. Subsequently a spark out cycle without infeed is performed using the same parameters. During pre-grinding and finish-grinding, the machine alternates the tooth positions in order to eliminate pitch errors.

Categories

All posts

- SCHNEEBERGER once again climbs the Mount Everest of grinding: Carbide Power Skiving Cutter Module 0.17 in the highest precision class

- The American Metalworking Community met at IMTS 2024; where SCHNEEBERGER presented the latest trends in CNC grinding technology

- SCHNEEBERGER GrindingHub Highlight 7/7: Maximum precision and productivity with the new Gemini NGM GHP, the Gear Hob Profiling Machine

- SCHNEEBERGER GrindingHub Highlight 6/7: High-End Components Manufactured with the Norma NGC

- SCHNEEBERGER GrindingHub Highlight 5/7: Norma NGC Scara, The Gear Cutting Tool Powerhouse