Profound Article in ORGANI DI TRASMISSIONE about today’s Requirements on Multifunctional Grinding Machines

«The almost exponential progress of electronics applied to machine tools and the refinement of mechanics and software allow to achieve extremely high levels of precision, flexibility and reliability. As in the case of grinding machines made by SCHNEEBERGER.»

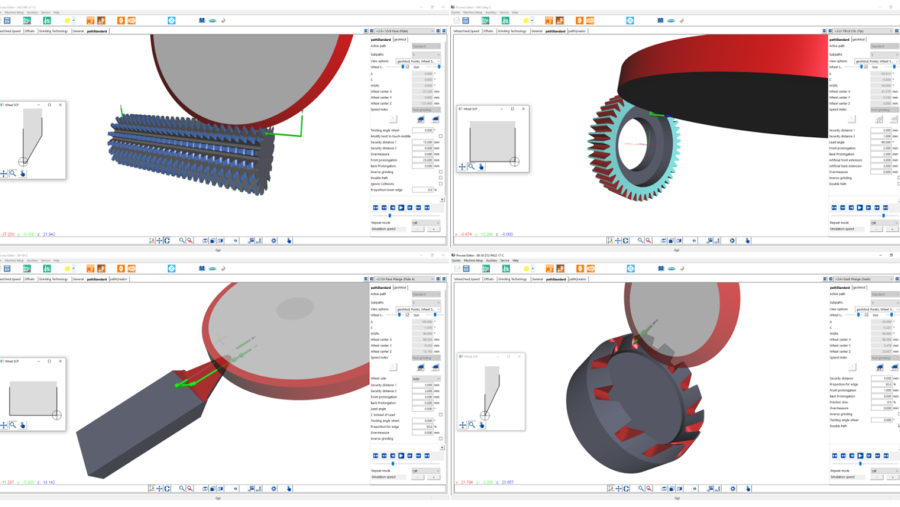

Gianfranco Bianco, a leading expert in the gear sector, dedicates a technical article to SCHNEEBERGER. It gives an overview about profiling and sharpening of gear cutting tools, such as hobs, shaper cutters, power skiving tools, stick blades, solid bevel cutters and broaches.

According to the article, SCHNEEBERGER grinding machines are known for “compactness, stability and the possibility of customization according to the actual needs”. Particular focus lies on the new Aries NGP+, which “given its compact design, generous axis travel and great flexibility is one of the most suitable solutions for tool resharpening in the gear manufacturing industry. Tools with a diameter and cutting length up to 400 mm can be ground”.

Read the full article here, by Gianfranco Bianco, Organi di Trasmissione, N.5_Maggio 2021

Categories

All posts

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- Reading tip: FORUM article on automation solutions for modern CNC grinding machines

- BRIANI and SCHNEEBERGER, a 30-year exemplary Collaboration for the Italian Tool Industry

- CCTV Business Report about Magally Technology reaches Millions of Viewers

- Turning the tides by going full CNC and automation in carbide insert production