Spindle power 10kW peak

Machine-integrated loader with a pallet

The filter system with its 200 liter tank enables filtration of oil or emulsion to 0.005mm. The filtration process takes place in the cylinder with two filter cartridges each.

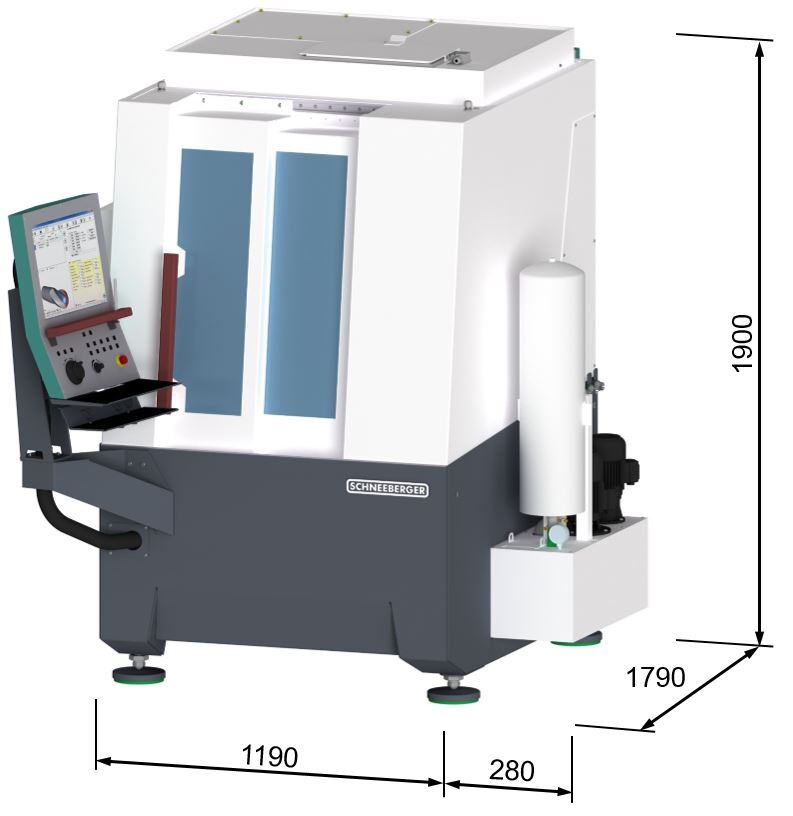

aries NGP+

5 axes CNC Tool Grinding Machine for sharpening and servicing of cutting tools.

The big sister of the ariesNGP: wider machine base, larger door openings and center heigth of 210mm. CNC Tool Grinding Machine for highest flexibility due to the innovative 5 axes machine concept. Best situated for sharpening of universal cutting tools, as well as production grinding of smaller batch tools. Tool dimension up to a diameter of 400mm and length up to 330mm fit perfectly in the ariesNGP+.

Generous work envelope, perfect SCHNEEBERGER machine quality and rigidity.

Accessories for the individual expansion of the application wealth and the advancement of productivity:

- Tool loader

- Direct scale system in all axes

- Tailstock manual

- Steady Rest manual

- Collet system, chucking arbors and insert holder

- Coolant filtration system

- Mist collector

- Co2 Fire extinguishing system

Applications

Video

Technical Data

Axes:

X: 420 mm (16.5”), longitudinal, linear bearings, ball screw, resolution 50 nm

Y: 360 mm (14.2”), cross slide, linear bearings, ball screw, resolution 50 nm

Z: 325 mm (12.8”), vertical, linear bearings, ball screw, resolution 50 nm

A: HSK 80 or ISO 50, work holder, resolution 0.0001°

C: 320°, rotation of the grinding head, resolution 0.0001°

Control:

FANUC 31i-B5, optional FANUC 0iF, 5 controlled axes

19” TFT color monitor, touch-screen, USB 3.0

Loader:

Integrated tool loader, tool pallet 200 x 200 mm (7.9” x 7.9”)

Grinding head:

Double ended grinding spindle, direct drive, HSK 50, liquid-cooled

5 kW (100%), 7 kW (60%) Max. speed 12'000 1/min

Weight:

2'000 kg (3‘409 lb)

Dimensions