SCHNEEBERGER NEWS

The latest trends from the world of 5-axis CNC grinding

New features of the CAD/CAM software Qg1, further machine development, customer reports and background information. All of that, only in SCHNEEBERGER NEWS.

More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

In a personal interview, Rolf gives insights into his career at SCHNEEBERGER: from the founding of the US subsidiary, through the development of important markets, to the handover to the next generation. With his joy for close customer contact and enthusiasm for new grinding technology, Rolf has mastered many challenges with flying colors. The SCHNEEBERGER team wishes him all the best for his well-deserved retirement

Read moreHappy Holidays

For all the excellent teamwork and your confidence, we want to sincerely thank you. We are looking forward to many more exciting projects in the coming years. Your SCHNEEBERGER team wishes for a successful 2026.

Read moreINSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

Insam Ewald now manufactures high-precision engraving tools using the Aries NGP 5-axis grinding machine from SCHNEEBERGER. With its high flexibility in tool design and fast robot loading, it brings a breath of fresh air to a tradition-conscious manufacturing environment.

Read moreAt Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

Gear hob, power skiving and shaper cutter profiling and sharpening have become remarkably efficient with SCHNEEBERGER Quinto Qg1 software. It also simplifies the sharpening of a wide range of cutting tools used in daily operations.

Read moreEMO 2025 - Thank you very much for visiting SCHNEEBERGER.

We presented the latest 5-axis grinding technology to our numerous visitors and discussed their future projects and needs with them. The range of applications for SCHNEEBERGER machines is virtually limitless, as is our motivation to find the perfect production solution for you.

Read moreEMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability

Small but powerful! It can handle numerous applications such as the production of profile mills, burrs, step drills, or the sharpening of skiving cutters with ease and in a fully automated manner. The most compact SCHNEEBERGER CNC grinding machine also has its fans at EMO, not least thanks to its newly developed steady rest.

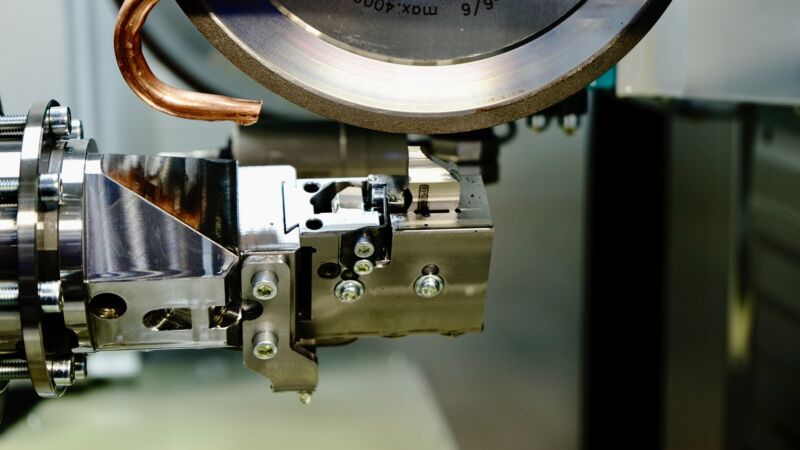

Read moreEMO NEWS 3/4: SCHNEEBERGER profiles Top Notch inserts in new cartridge clamping system

Sirius NGS is the renowned grinding machine for the manufacture of micro tools and profile indexable inserts. The distinctive machine kinematics, linear motors, and directly driven rotary axes forms a rock-solid foundation.

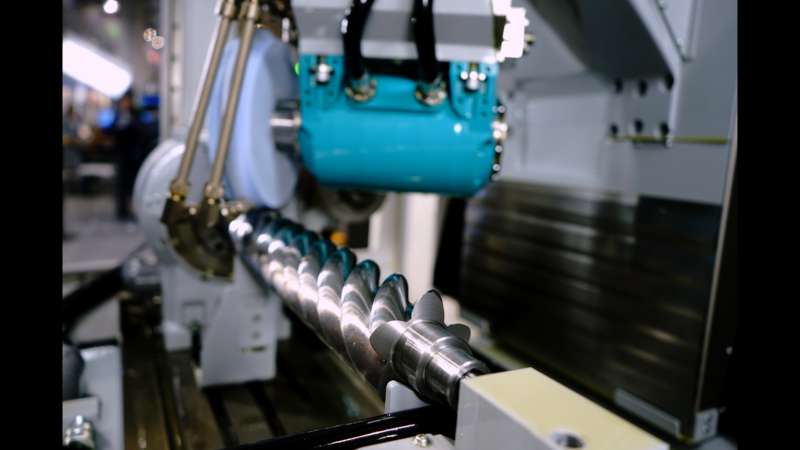

Read moreEMO NEWS 2/4: Norma NGC 750 grinds geometrically complex compressor screws with high precision

The application demonstrates all of its strengths: the long version of the 5-axis Norma NGC with a 750 mm X-stroke is rock-solid, precise, and compact. Together with Quinto Qg1, it masters a wide range of precision parts manufacturing tasks.

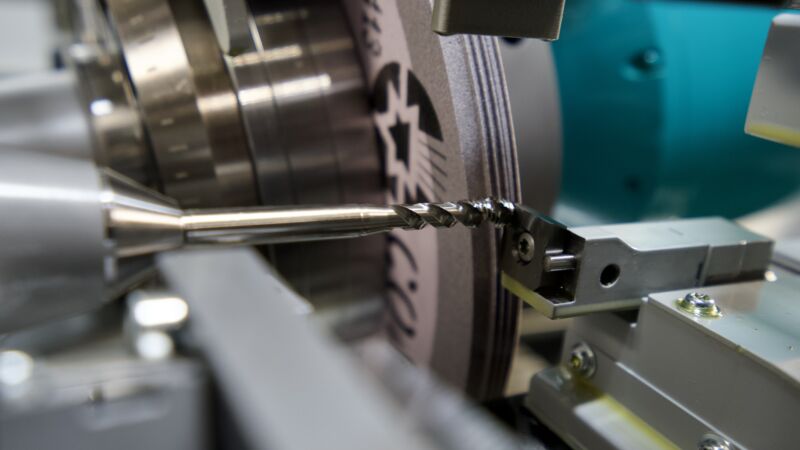

Read moreEMO NEWS 1/4: SCHNEEBERGER celebrates the world premiere of the latest generation of Gemini NGM TAP

The newly developed special version of the Gemini is aimed at top-class tap production. It has never been so easy and efficient, because the new Gemini NGM TAP grinds threads, cutting edges, and flutes with great power.

Read moreSCHNEEBERGER Service Seminar 2025

SCHNEEBERGER customers are supported by highly trained specialists. Continuous training on technology, grinding applications, and maintenance topics is essential for this.

Read moreVisit SCHNEEBERGER at EMO 2025

SCHNEEBERGER presents numerous innovations in 5-axis CNC grinding in 2025. Come and get inspired in Hall 11, Booth E78.

Read moreCongratulations to Manuel and Lorent on completing their apprenticeships!

Manuel Vonaesch (automation technician EFZ) and Lorent Beqaj (polymechanic EFZ) have passed their apprenticeship at SCHNEEBERGER brilliantly. Many congratulations. We wish you every success in your future careers!

Read more