At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

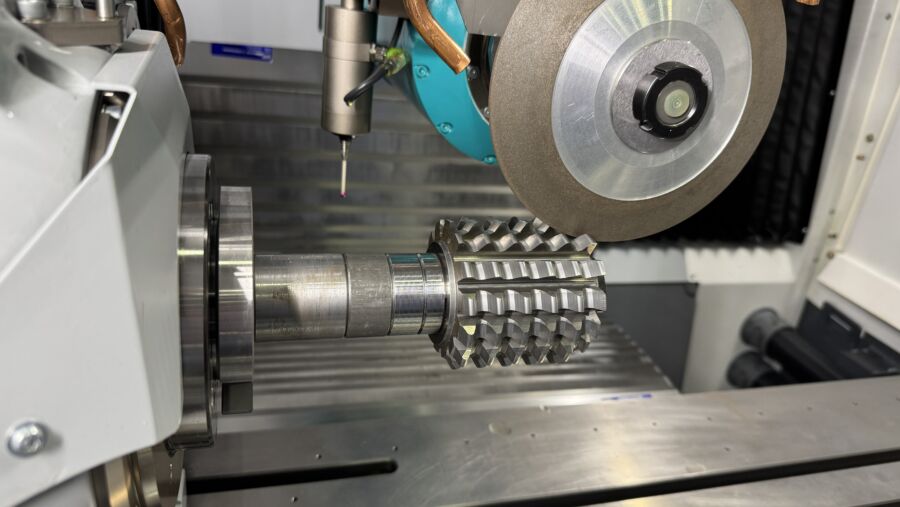

Gear hob, power skiving and shaper cutter profiling and sharpening have become remarkably efficient with SCHNEEBERGER Quinto Qg1 software. It also simplifies the sharpening of a wide range of cutting tools used in daily operations.

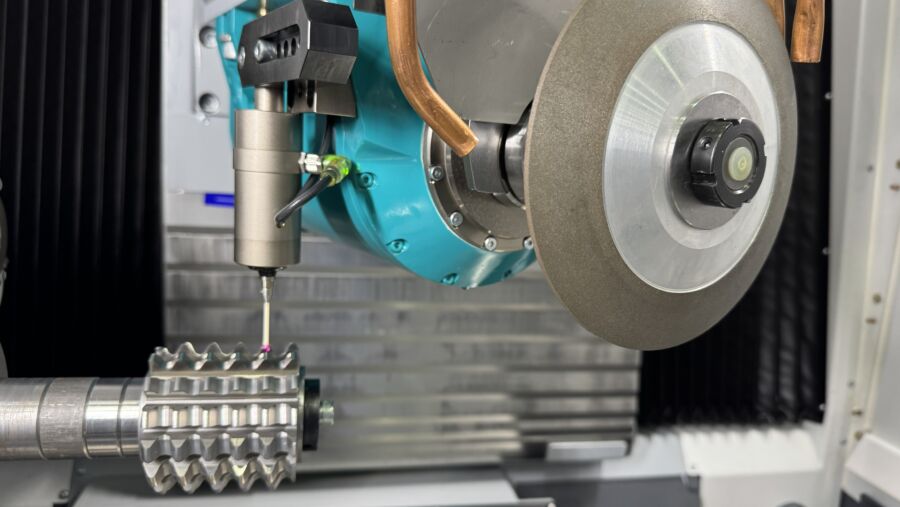

The Norma NGC demonstrated its flexibility and compact footprint with a work envelope of up to 14” diameter x 24” long, at the MPTE 2025 in Detroit. Visitors appreciated its wide range of applications for tool manufacturing and sharpening, as well as the impressive capabilities of the Qg1 CAD/CAM software.

Hob sharpening was at the center of attention — from precise tool probing to the generation of detailed quality reports within the CAD/CAM software. Switching between helical hobs and power skiving cutters is effortless, thanks to the generous working space and flexibility of the Norma NGC.

We would like to thank all visitors for taking the time to stop by our booth. It was a pleasure reconnecting with our valued customers and meeting new organizations interested in our technology.

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability