INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

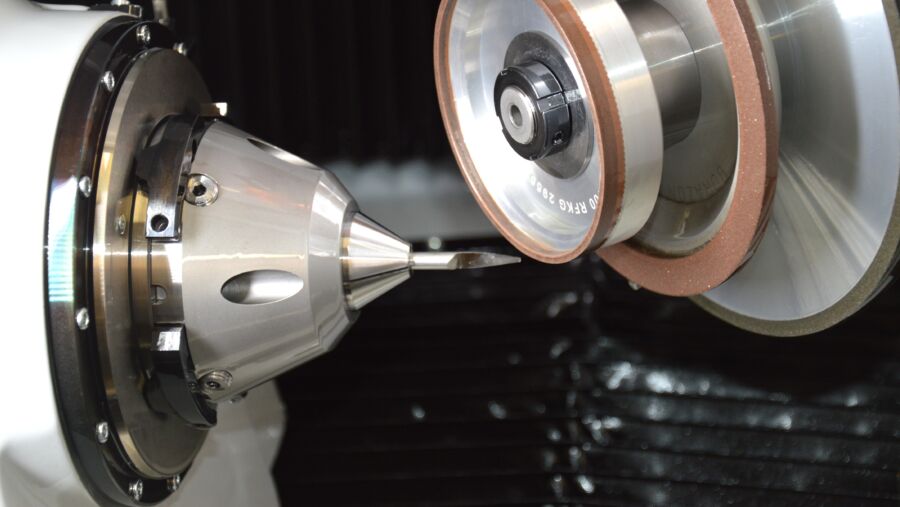

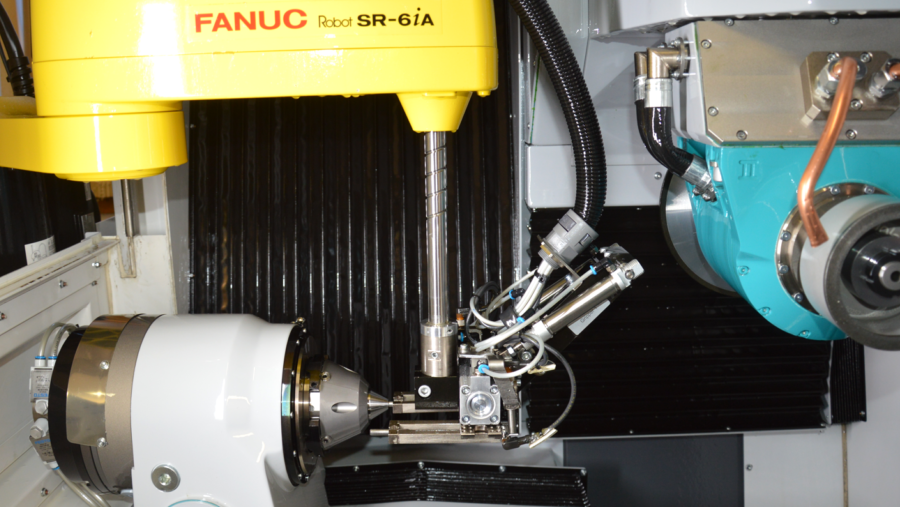

Insam Ewald now manufactures high-precision engraving tools using the Aries NGP 5-axis grinding machine from SCHNEEBERGER. With its high flexibility in tool design and fast robot loading, it brings a breath of fresh air to a tradition-conscious manufacturing environment.

The Insam Ewald Company

Alpinism, tourism and artistic woodworking have a long tradition in Val Gardena, South Tyrol, and have had a profound influence on the valley and its inhabitants. Insam Ewald and his wife Margherita began their work as woodcarvers in 1979. Since 1990, the business has been located in St. Ulrich, the main town in the Val Gardena valley. The production of wooden figures is based on a bronze model made by sculptors on a scale of 5:1. A copy milling machine produces dozens of statues simultaneously.

Simon and Lukas Insam are continuing the tradition today, expanding the product range and integrating new technologies into production. This is where Insam Ewald meets SCHNEEBERGER: woodworking is traditionally influenced, but cannot do without the use of perfect tools. Precise engraving cutters guarantee consistent quality across the entire production batch.

The new investment in a 5-axis CNC machine Aries NGP

How can you efficiently manufacture thousands of tools per year that are all identical and powerful? How can you further develop tools that are optimized for milling performance? To do this, you need two things: an excellent CNC machine and sound grinding technology support. The Aries NGP from SCHNEEBERGER, assembled at the Italian plant in IT-Costermano, is precise, stable and economical. With its FANUC Scara robot with short loading times, it can even produce large series efficiently. Equally important is the support provided by SCHNEEBERGER's well-trained application engineers. They not only explain how to operate the machine, but also give valuable tips on how to produce perfect tools in a reasonable amount of time. At Insam Ewald, the machine operator programs the tool in the office, where he studies and evaluates the design in detail using 3D simulation. The program also includes the loading and unloading processes with the Scara robot. Once the machine is started, it begins unmanned series production of engraving tools.

SCHNEEBERGER wishes Insam Ewald success with its in-house production of engraving tools. Especially now, during the peak season for wooden crib figures, we are delighted to contribute to your success.

Categories

All posts

- Happy Holidays

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability

- EMO NEWS 3/4: SCHNEEBERGER profiles Top Notch inserts in new cartridge clamping system