EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability

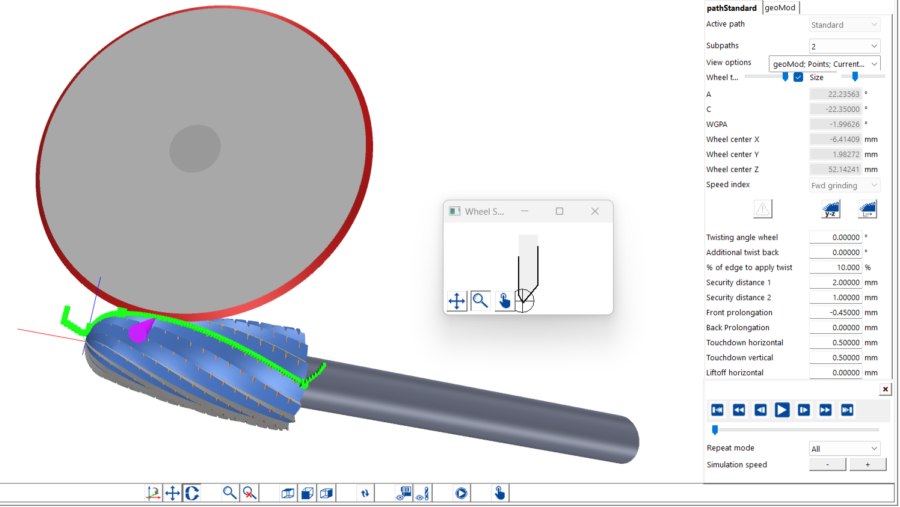

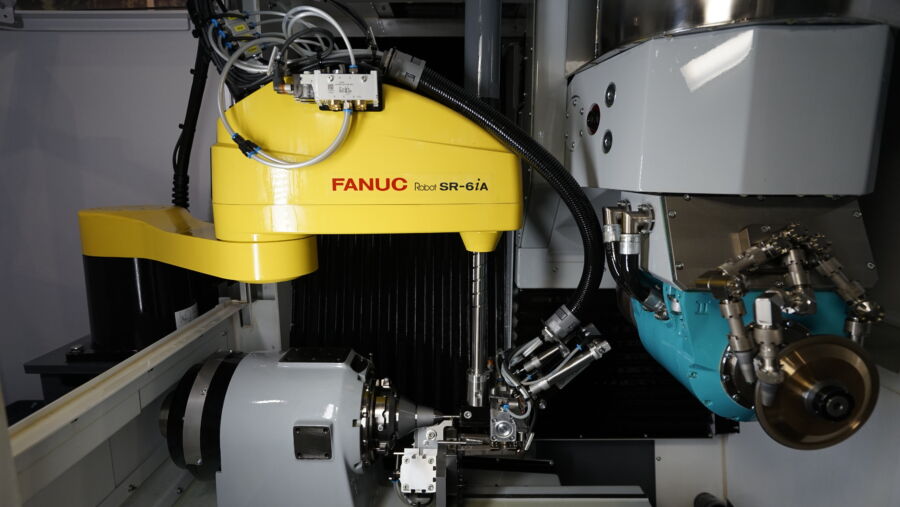

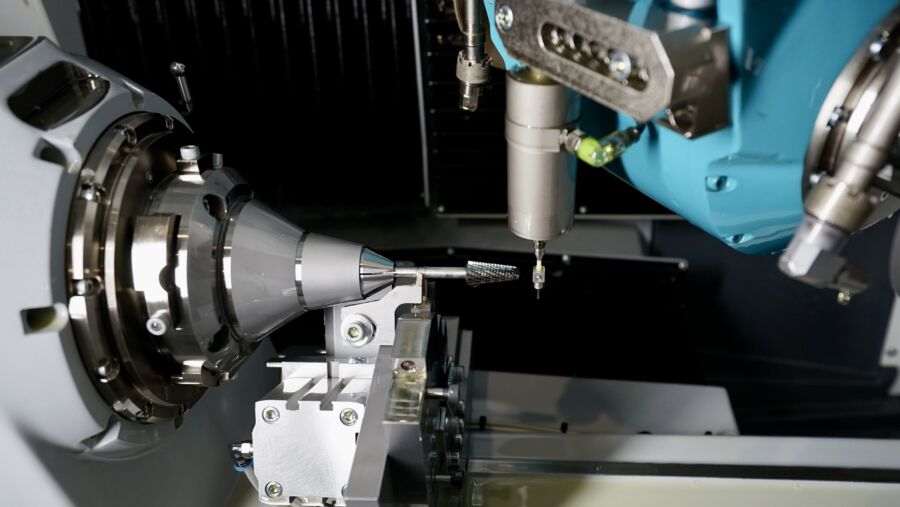

Small but powerful! It can handle numerous applications such as the production of profile mills, burrs, step drills, or the sharpening of skiving cutters with ease and in a fully automated manner. The most compact SCHNEEBERGER CNC grinding machine also has its fans at EMO, not least thanks to its newly developed steady rest.

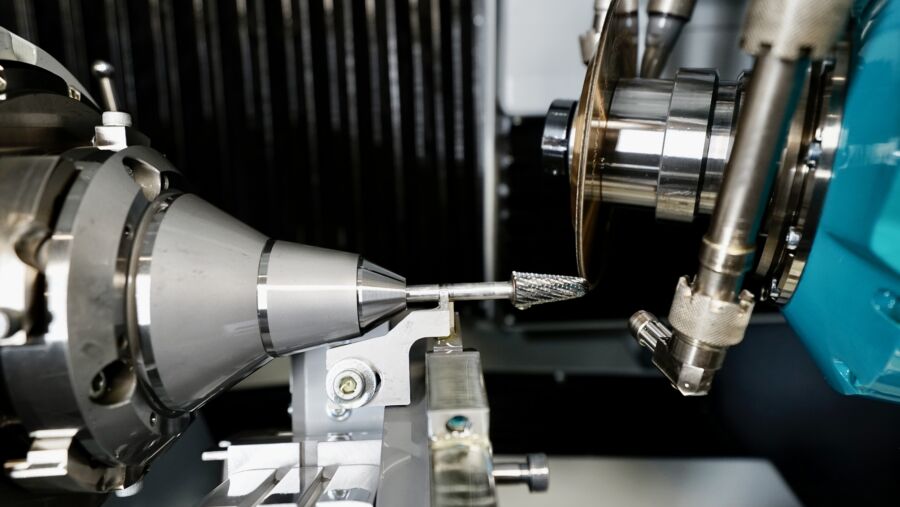

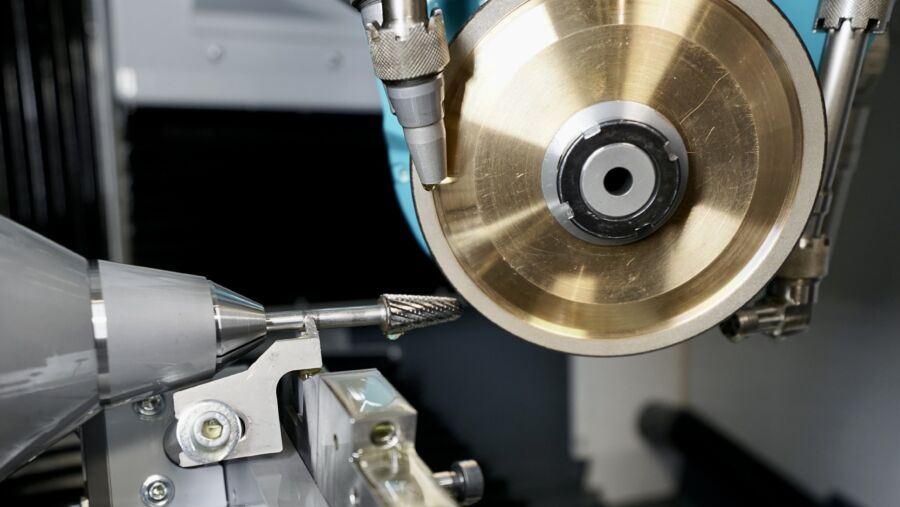

The importance of a perfect steady rest cannot be overestimated. With its wide V-shaped support surface, it determines the tool orientation more than the collet, which is reduced to the drive when clamped short. The hold-down device presses reliably and has a dampening effect on the tool. The support surfaces of both the chuck and the hold-down device are designed specifically for the application and support the grinding process. The newly developed SCHNEEBERGER steady rest contributes significantly to precision and consistency in small and large series production.

Despite its minimal footprint of 2.5 m², the 5-axis Aries NGP impresses with a remarkable stroke of X 420, Y 360, and Z 260 mm. The elegantly integrated Fanuc Scara robot changes tools in 7 seconds and has sufficient autonomy with 4 pallets. The torque motor-driven A-axis also allows circular grinding operations at up to 1,000 revolutions per minute. All this in a compact machine, including 200L cooling lubricant filtration, active cooling, and extraction.

Grinding applications from small to large, in a wide variety of materials, the main thing is 5-axis technology, the main thing is SCHNEEBERGER.

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.