The company history

J. SCHNEEBERGER Maschinen AG has been developing and producing precision grinding machines since 1923.

From the outset, striving for the greatest degree of universality and maximum precision and up to date with a broad product range of grinding machines with integrated robotics.

Expansion in Italy

New factory building for our Italian subsidiary. In Costermano sul Garda, space was created to further expand our production capacity in Italy. 4000 m2 of production floor and office space are now available. In addition, more space has been created for demo machines in the show room.

Enlargement of the branch in the USA

Movie in Elgin. More space for machine showroom, warehouse and workshop and spacious office facilities on 1160 Abbott Drive. Not far from Interstate 90 and therefore easily accessible. A modern demonstration center is available for our customers and the large warehouse ensures rapid availability of spare parts.

New demo room in Roggwil

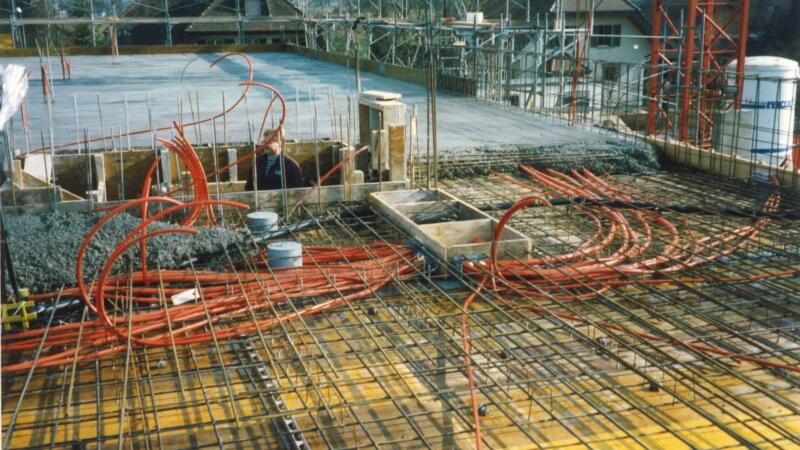

400 m2 of light-flooded exhibition space with modern supply system. 12 manifolds supply up to 24 machines with coolants, electrical power and compressed air. The latest cooling, heating and air cleaning equipment ensure a pleasant climate.

The premises are used as a showroom, for customer training and for application development.

corvusNGB, any size goes !

The machine for producing and regrinding broach tools, granulate mills, racks, and much more excited the technical visitors at the EMO with extended travel paths, more power, faster feed speeds, and modern design. The displayed model featured over 2,100 mm axis travel path in the X direction and 400 mm in Y and Z. The stability and turning torque were also increased.

New blood at SCHNEEBERGER grinding machines

At GrindTec 2016 a new member of the range of grinding machines was presented: ariesNGP, although just 99 cm wide, it is still no lightweight. At 1700 kg the new machine sits stably on the floor. With a construction height of 1 m and 76 cm, it has very appealing proportions.

Expansion for SCHNEEBERGER China

Our Chinese subsidiary has moved. Ca. 10 km to the south of the current location, in new premises on Shui Ge Road No. 8, Nanjing. The new head office offers considerably more space to accommodate the development of our company.

sirius NGS, microns or less!

The machine for precision engineering. Compact construction and so a spatial requirement of just 3 m2, ideal 6-axis kinematics concept, linear and torque motors, 6-axis robot from Fanuc, 2-pallet loader and optional grinding wheel changer with 7 changer positions.

geminiNGM, you name it!

The powerful and multifaceted high-tech grinding machine for countless production tasks. The Fanuc robot with 2 or 4 pallet loader in combination with the grinding wheel changer with 14 or 25 positions, high-torque motor grinding spindles with up to 24 kW, workpieces up to 450 mm in length and can be used with grinding wheels up to 300 mm in diameter.

New premises for SCHNEEBERGER Germany

Our German subsidiary in Weissach near Stuttgart has relocated to new premises. The company's move has taken it just 800 m from the former premises, Im Neuenbühl 16, to a brand new building. The new company headquarters cover the space requirements of the expanding business.

norma NGC, GrindTec 2014

State Secretary, Franz Josef Pschierer, the General Secretary of the Central Association of German Trades, Holger Schwannecke, and the president of the FDPW, Jürgen Baldus played a central role at this première. The machines from the ngc model range were exhibited in three display versions, and were literally electrified.

geminiTAP, tap production

Intended specifically for the production of thread taps, this machine was first presented at EMO 2013 in Hanover. The thread taps are ground on flutes, threads and cuts, in a single clamping.

CNC machining center

New, flexible manufacturing concept with FMS for important mechanical parts. 58 workpiece pallets, 400 tools in the change station.

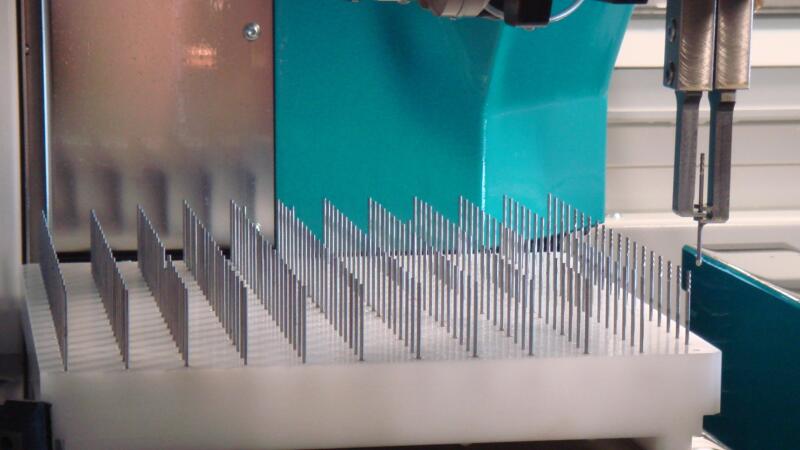

Optical position detection

The vision system is introduced for identifying the positions of workpieces during cutting insert production on the SIRIUS. Flexible, autonomous mass production!

A subsidiary in China

August: Formation of a subsidiary in China The headquarters is in Nanjing in the Jiangsu province.

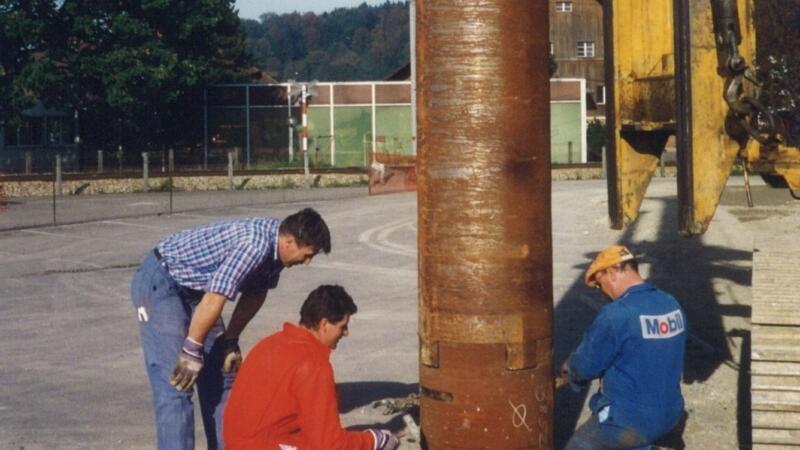

New construction in Roggwil

Extension for mechanical and electrical installation, fitting shop and storage facility at the main site in Roggwil.

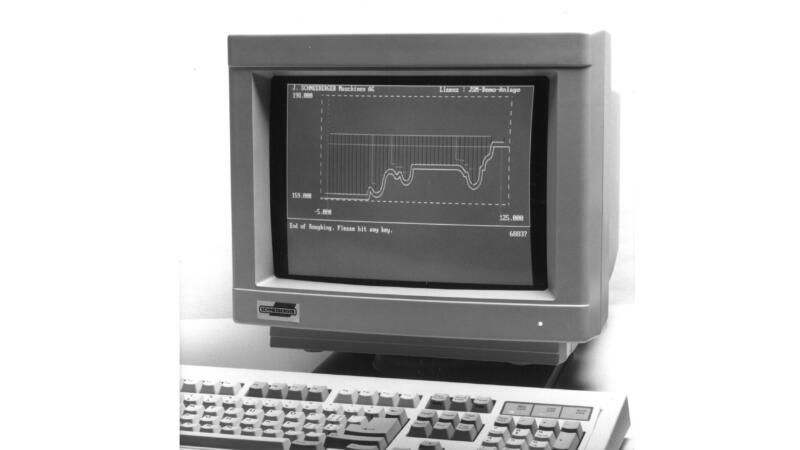

dxQ profile software

Revolutionary grinding software is presented with ergonomic controls for sophisticated profile tools.

Flexible automation

First articulated arm robot to be used in tool grinding - pioneering work from SCHNEEBERGER.

New construction completed

The new production and administration premises were opened at the company base in Roggwil in January 1997.

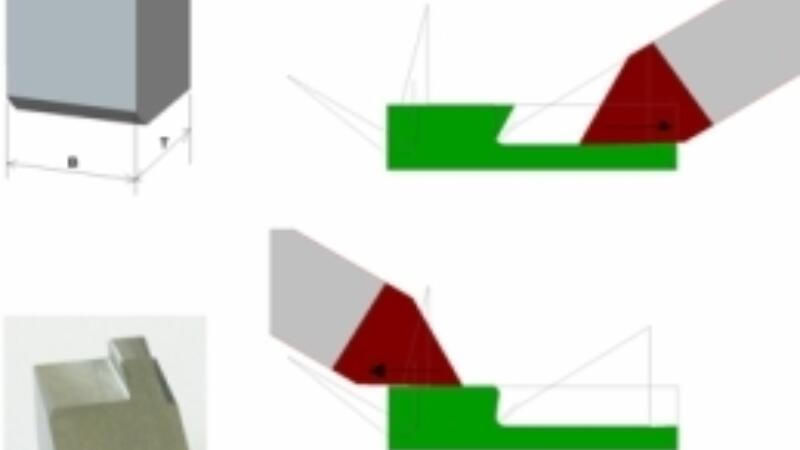

Optical position checking

Optical Profile Control (1997) on the grinding machine introduced the principle of in-process measuring into tool grinding. The tool profile is examined for compliance with target values by means of a high resolution CCD camera, and any profile deviations are corrected automatically.

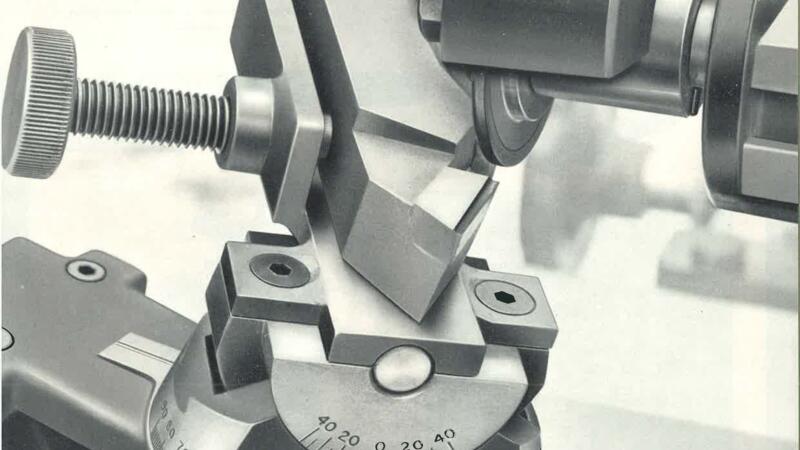

Technology of the 60s

The heyday of purely manual tool grinding machines.

With a multitude of setting axes and scales, the cunning grinder hand could realize almost any geometry.

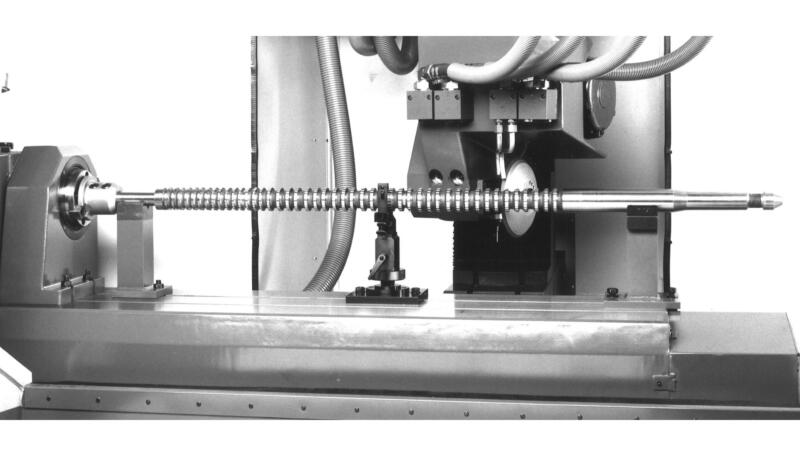

SCHNEEBERGER was also a manufacturer of customized special machines

for the optical industry or the shoe industry and, as component of a grinding machine

for carbide tools, has invented the linear roller guide.

First visit to a trade fair with the full range

For the first time, SCHNEEBERGER presented their whole grinding machine range at a trade fair.

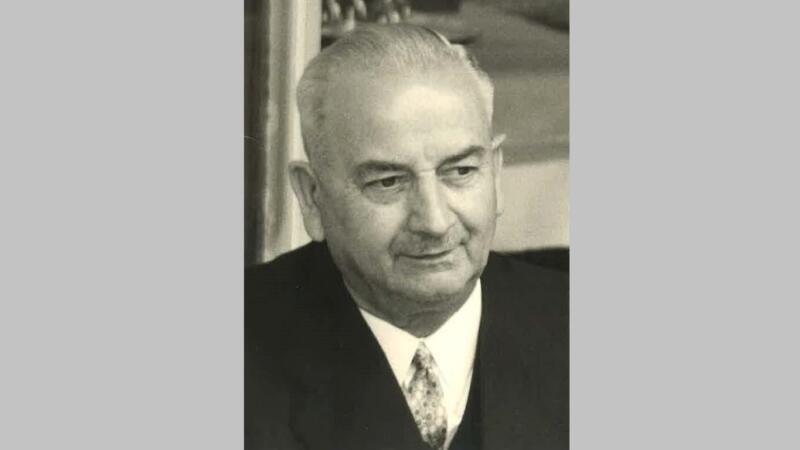

Company foundation 1923

Walter Schneeberger, born in 1890, learned the trade of mechanic at the U. Ammann machine factory in Langenthal and gained further experience with jobs in Basel, Zurich and Langenthal.

On 1 March 1923 with a thousand francs in start-up capital, he founded his company in his father-in-law's house in Roggwil: W. SCHNEEBERGER, Werkzeuge und Maschinenbau.