Careers

Be part of the success, come and join us. We turn up the heat!

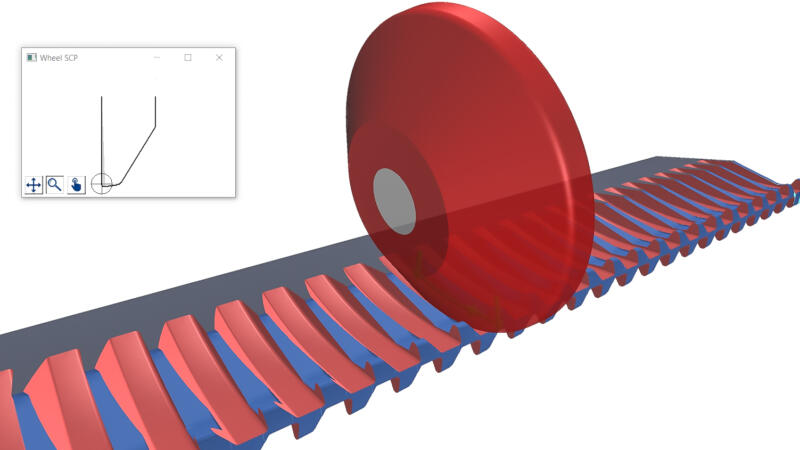

Tool grinding machines and state-of-the-art systems equipped with the latest robotics and software technology. The production of high-precision parts tools is taken care of by highly trained specialists with the latest equipment. Engineers develop new processes, software and create innovative mechanical concepts. ERP, planning and logistics form the basis of the production.

As an employer, we consider progressive employment conditions, excellent social benefits and flexible working hours to be part of our success.