EMO NEWS 1/4: SCHNEEBERGER celebrates the world premiere of the latest generation of Gemini NGM TAP

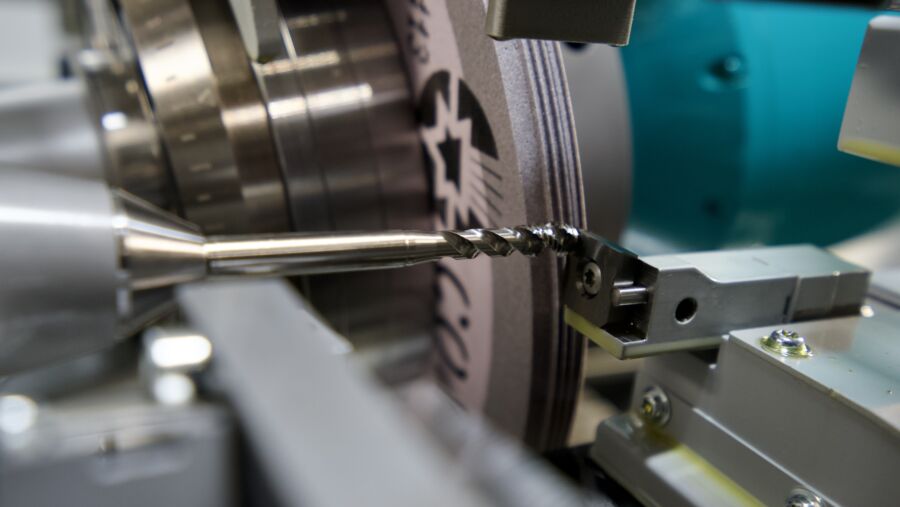

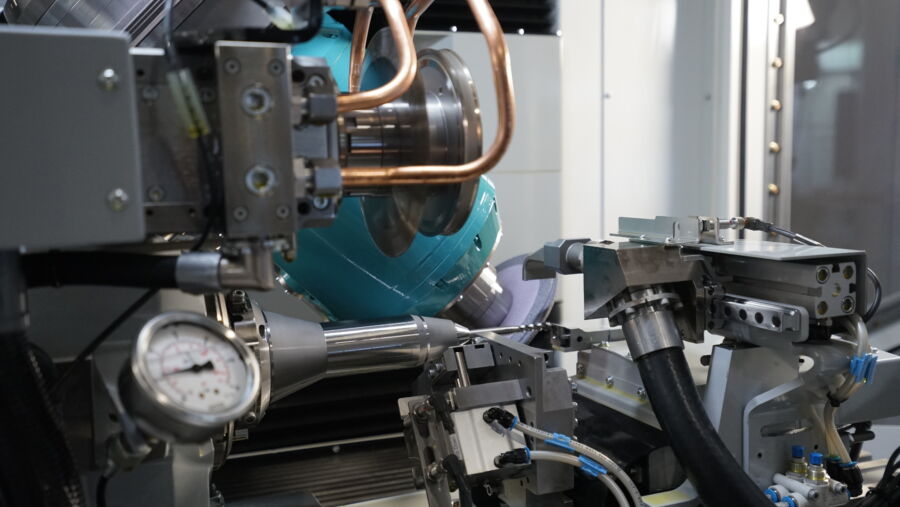

The newly developed special version of the Gemini is aimed at top-class tap production. It has never been so easy and efficient, because the new Gemini NGM TAP grinds threads, cutting edges, and flutes with great power.

The powerful 24 kW spindle (S1), direct-drive axes, and rock-solid machine construction make it possible. The All-in-One machine concept scores with batch size flexibility, short setup times, and reduced personnel costs thanks to a short production chain.

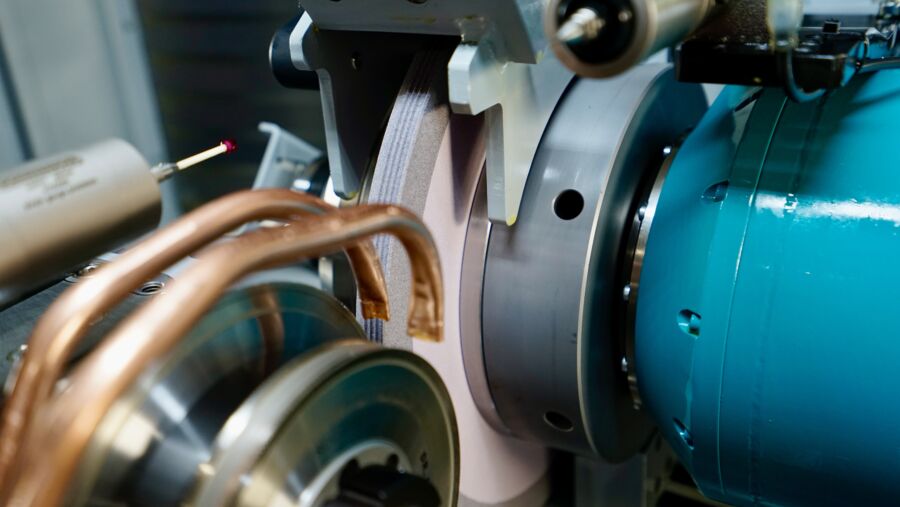

Efficient thread grinding is possible thanks to the highly dynamic Y-axis. Weight-optimized and directly driven, the axis oscillates so slightly that it is barely noticeable to the eye. SCHNEEBERGER draws on its many years of experience in linear motor technology for this application.

At EMO, the process will be demonstrated on M4 and M8 thread taps, each with straight and spiral flutes. Unidirectional coolant nozzles optimized for the application enable short cycle times for all processes.

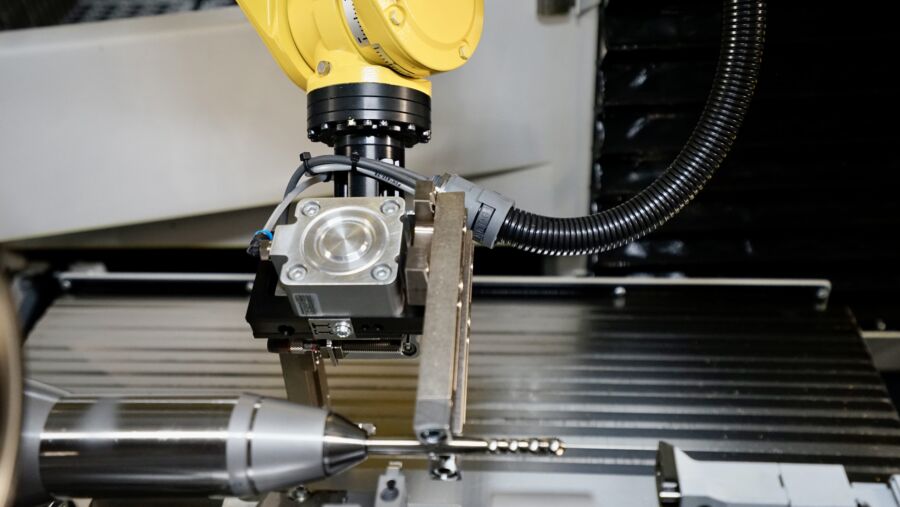

The new dressing unit from SCHNEEBERGER with acoustic sensor shapes the threaded disc. A second dressing roller shapes the grooved disc. The results are precise and reliable, even in 24/7 operation. Robotic loading, a core competence of SCHNEEBERGER, is a matter of course for a TAP production machine. Four or, optionally, ten pallets meet all requirements for modern production autonomy.

SCHNEEBERGER is delighted to open this new chapter with the trade fair audience. Come by and let our tap enthusiasm rub off on you. Hall 11, Booth E78.

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.