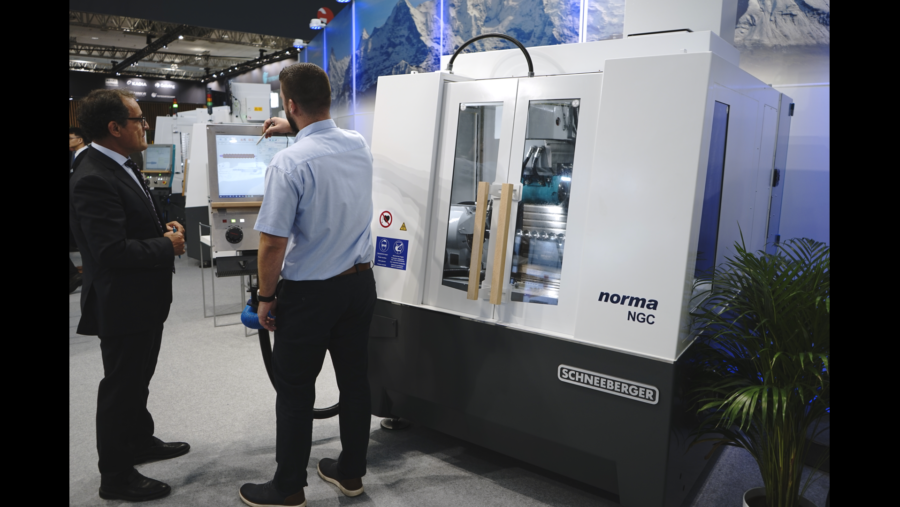

EMO NEWS 2/4: Norma NGC 750 grinds geometrically complex compressor screws with high precision

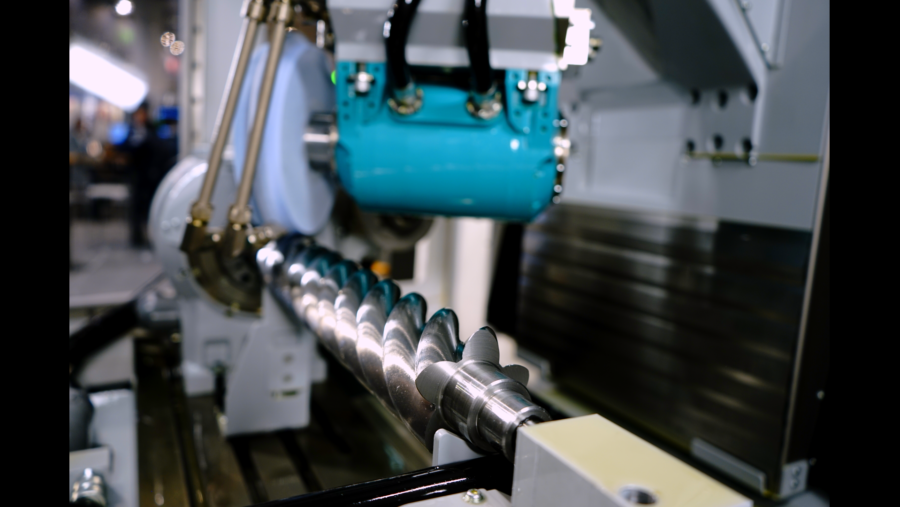

The application demonstrates all of its strengths: the long version of the 5-axis Norma NGC with a 750 mm X-stroke is rock-solid, precise, and compact. Together with Quinto Qg1, it masters a wide range of precision parts manufacturing tasks.

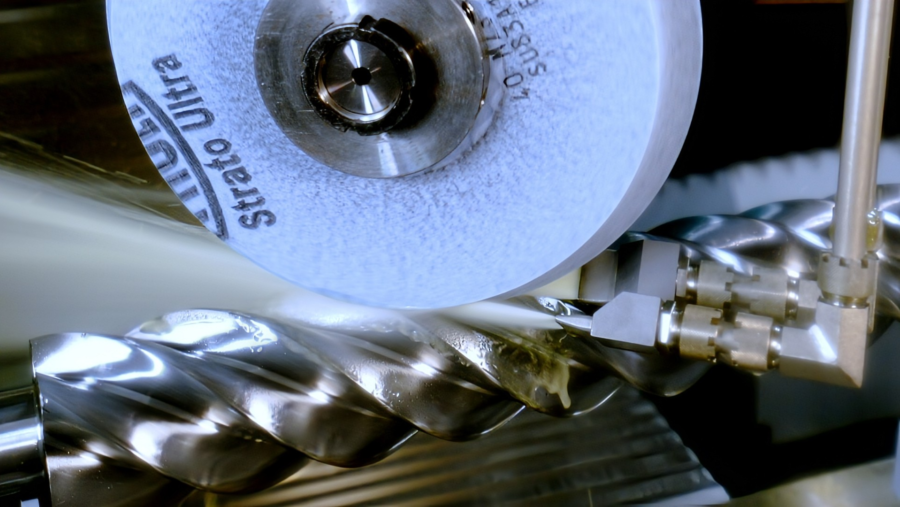

Compressor screws are used in compressed air systems, refrigeration technology, and process gas compressors. The more precise the screw geometry, the more efficient and resource-saving the end product. That is why investing in a SCHNEEBERGER quality machine is worthwhile.

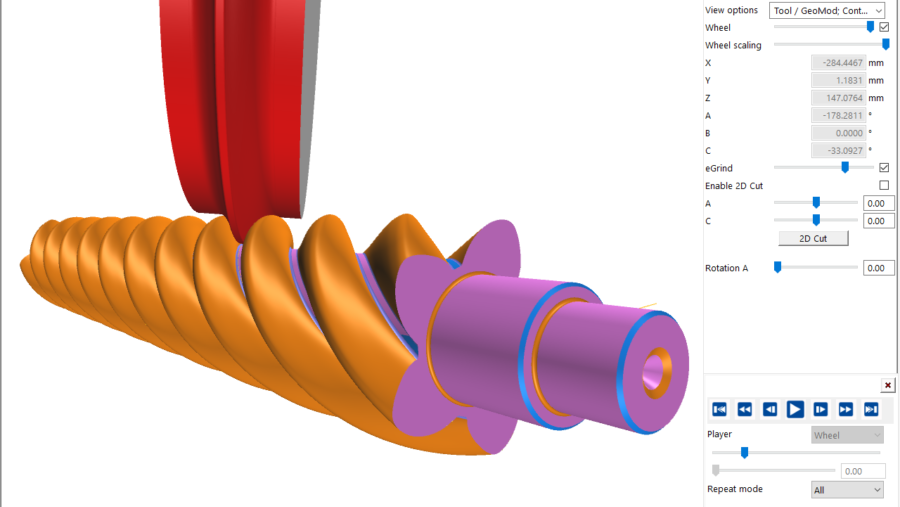

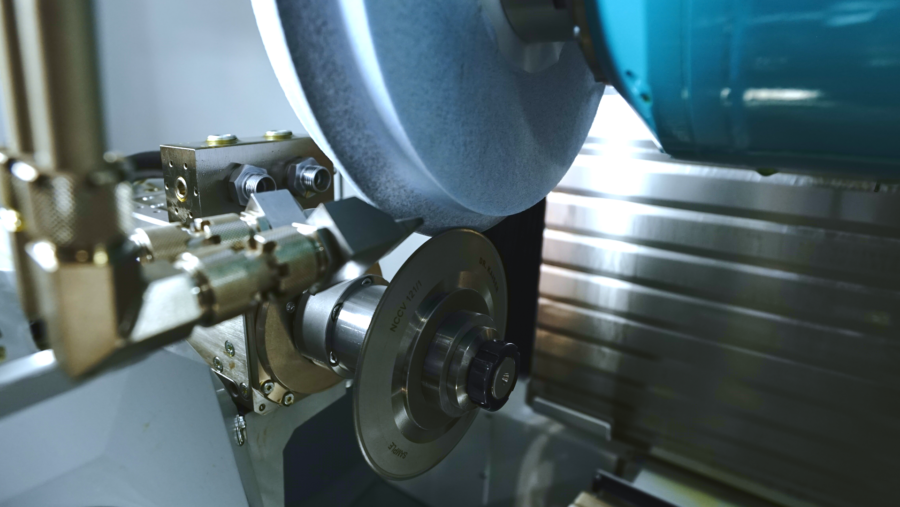

The Quinto Qg1 CAD/CAM software with 3D model import is the first choice for unlimited component geometry. Based on the screw shape, Qg1 calculates the resulting form grinding wheel in just a few clicks, with or without pitch. The SCHNEEBERGER dressing spindle is an important component for success. Extremely thermally stable, with speeds of up to 12,000 rpm,

the dressing parameters are freely selectable.

Held between centers, the compressor screw is perfectly aligned. The driver drives it precisely, free of transverse forces and backlash. With 50 mm wide grinding wheels, a powerful grinding spindle, and process cooling with a high volume flow, the Norma NGC is an efficient production machine.

What are you grinding? SCHNEEBERGER has extensive experience in the production of components: turbine blades, drive technology, medical implants, fluid technology, or perhaps exactly what you have in mind. Visit us at EMO, Hall 11, E78, or contact our global grinding technology consultants.

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.