EMO NEWS 3/4: SCHNEEBERGER profiles Top Notch inserts in new cartridge clamping system

Sirius NGS is the renowned grinding machine for the manufacture of micro tools and profile indexable inserts. The distinctive machine kinematics, linear motors, and directly driven rotary axes forms a rock-solid foundation.

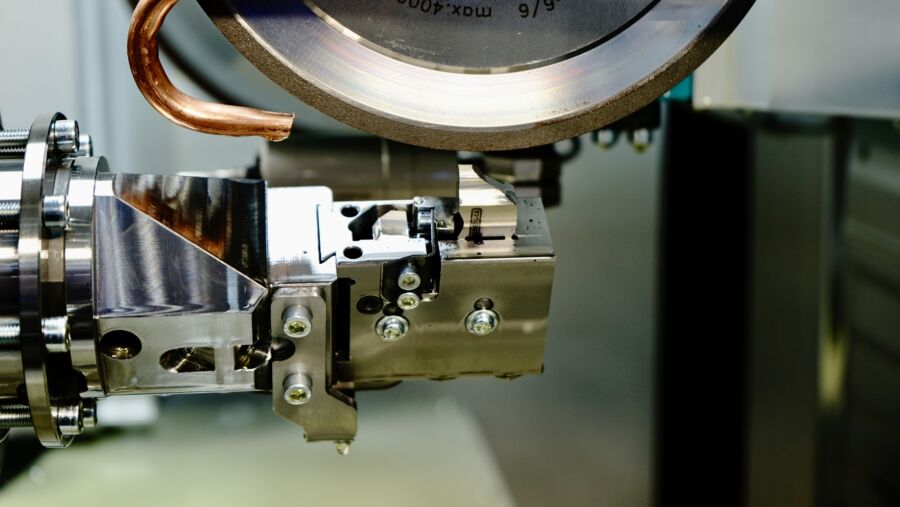

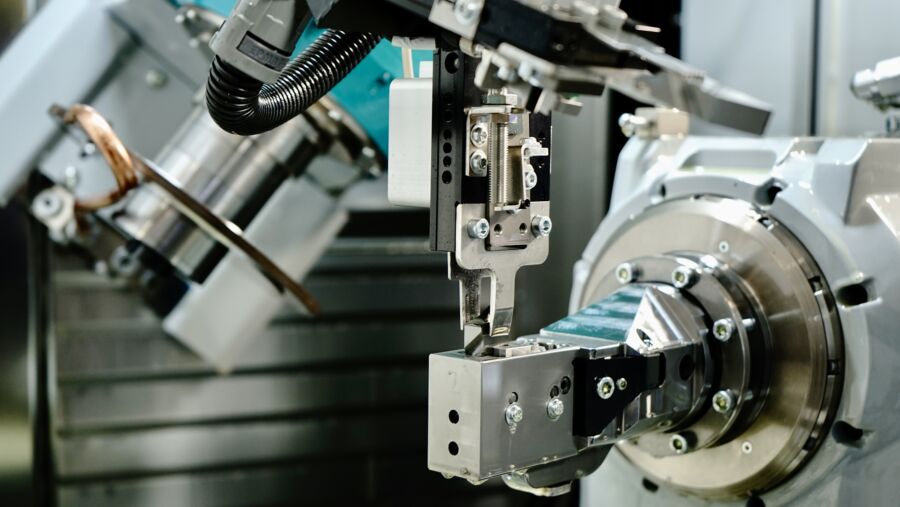

The enclosed cardridge clamping system secures the workpiece at two reference surfaces and the longitudinal stop. Indexable inserts remain firmly in position and reliably withstand all process forces. The adjustable contact pressure is distributed evenly across the defined contact points. The grinding wheels are accessible for a wide range of clearance angles. Automatically rotated and clamped with repeatable accuracy, the result is the typical point-symmetrical top-notch profile plates. After an intensive development phase, SCHNEEBERGER is presenting the latest generation of cardrdige clamping devices at EMO 2025.

The four grinding wheels, measuring up to Ø300 mm, enable a stable production process. The latest SCHNEEBERGER technology in the dressing process has also been incorporated into the Sirius NGS. All expectations regarding profile precision and surface quality have been exceeded. In-process measurements, whether tactile or laser-based, provide additional confidence for 24/7 production. Robot loading and automatic laser marking round off the package.

Does your indexable insert production need a technological boost? SCHNEEBERGER is the right place for you!

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.