Live from EMO, Day 2: Skiving Cutters Profiling in Large Series, with the Gemini NGM, Day In and Day Out in AAA.

SCHNEEBERGER leads the way: Fully automated production of gear skiving cutters of various sizes and modules, live at the trade show!

Profiling of shaper and skiving cutters is the Champions League of tool grinding. SCHNEEBERGER now also offers this demanding grinding process in automated mixed production. 40 blanks up to diameter 200 are provided in a robot arena. Thanks to a uniform mechanical interface, the large FANUC robot can load and unload different tools. In contrast, the 8-position wheel changer contributes significantly to the autonomy; It reliably changes the shaping wheels for profiling (roughing and finishing wheels) as well as other wheels for face and collar machining.

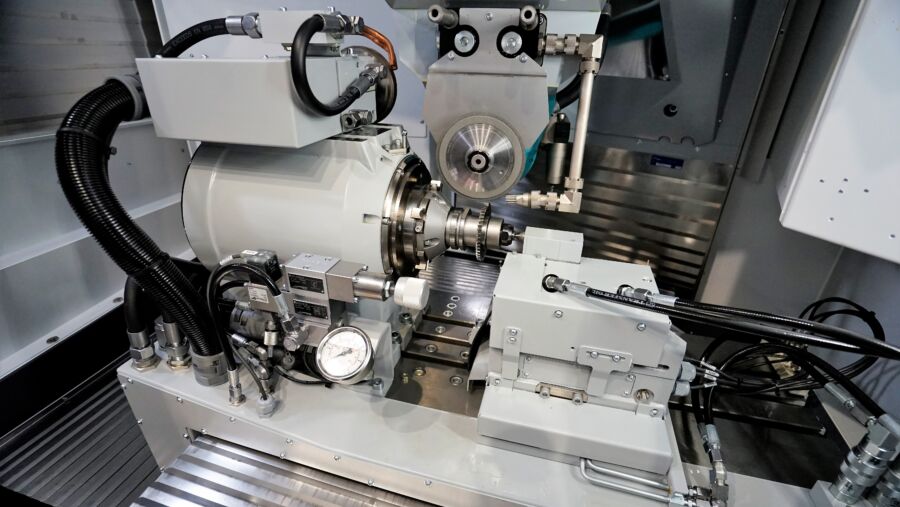

The heart of the system is the rock-solid Gemini NGM 5-axis grinding machine. Equipped with linear and torque motors, it is perfectly suited for dynamic part-roll grinding of the profile. A high-frequency dressing unit with structure-borne sound sensor and a grinding wheel sensor guarantee the consistently precise grinding result - on 6 measuring days or every day in your production.

Stay tuned with SCHNEEBERGER, live from Hannover, Hall 6, Booth G23.

Don't miss: The Anniversary Booth Party on Wednesday from 5 pm.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability