Live from EMO, Day 3: Norma NGC750, the legend continues with the enlarged version of SCHNEEBERGERs best-selling machine

Norma NGC750 is popular worldwide for sharpening all types and sizes of gear cutting tools. An economical system, yet suitable for oversized tool.

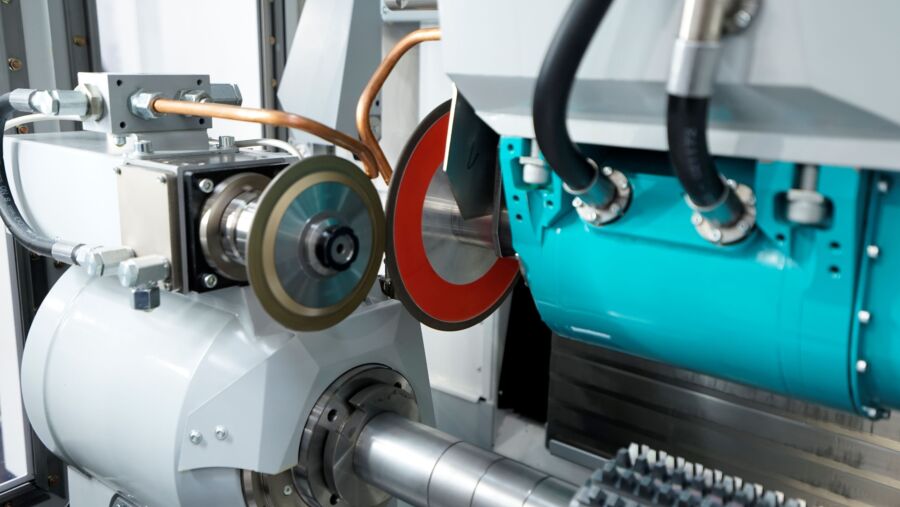

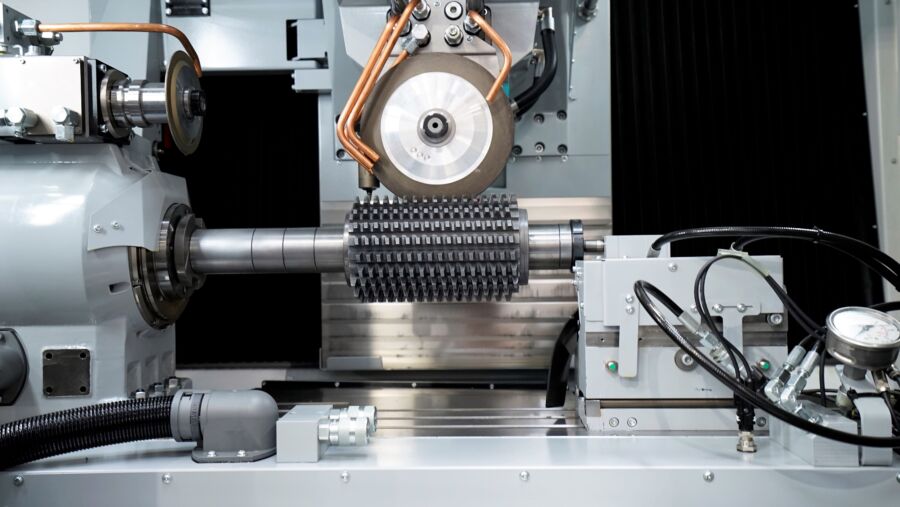

Norma NGC750 comes with a 750mm X-stroke instead of the standard 470mm. The 5-axis grinding machine expands the broad SCHNEEBERGER portfolio and unbeatable cost performance for grinding big tools. Examples of tools, but not limited are; long gear hob or complex hob in one body, shaper cutter and skiving cutter sharpening, solid carbide long drill for deep hole drilling or oversized taper ball nose milling cutter and sharpening for turbine industry. At EMO, a big hob with 320mm long cutting edge, 180mm diameter and several rotary tool sharpening are shown. Seven positions grinding wheel loader and MIL part loading system ensure maximum productivity. Optional items like CNC following steady rest, hydraulic tailstock or SCARA robot can be implemented upon actual application.

The Qg1 CAD/CAM grinding software provides quick and easy programming of various tools. Toogle, the rich database for nearly all kind of tools requires a few simple steps to get an individual and optimized grinding program.

If you have a challenge with big tools, then please visit SCHNEEBERGER in EMO Hannover, hall 6, booth G23.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability