Live from EMO Milan, Day 2: Skiving Cutter Profiling on Sirius NGS

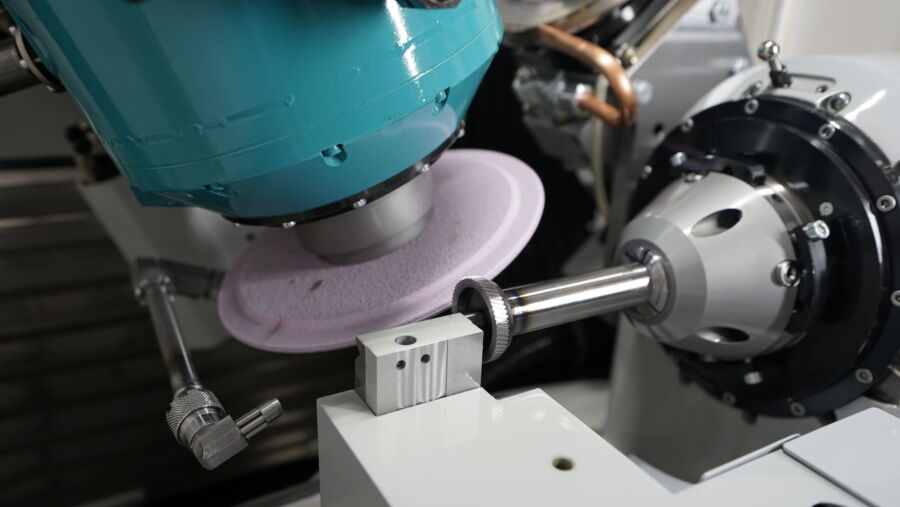

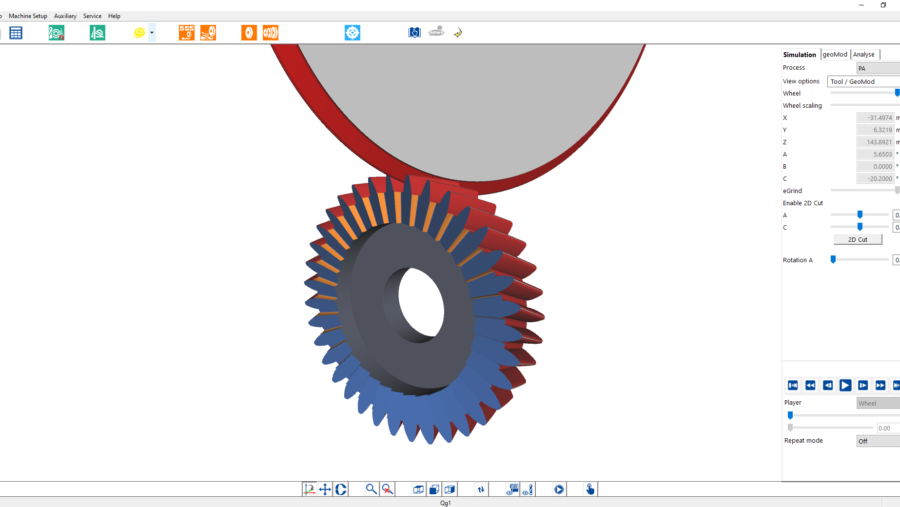

SCHNEEBERGER makes it happen at the show: Production of skiving cutters in highest precision, efficiency and even with full robot autonomy

Achieving highest AA precision standards starts with a sophisticated clamping system. Concentricity is given by a precisely adjustable A-axis clamping and a hydraulic tailstock as a counterpart. The grinding process is about finding the right balance between gentle infeed and yet efficient material removal. This requires dynamic movements, driven by linear motors and direct drives. Compact and rigid machine structures enable these dynamic movements. Thanks to the Sirius NGS machine kinematics, only a limited number of axes are simultaneously oscillating.

In addition, full robot autonomy opens doors to a true serial production.

Stay tuned with SCHNEEBERGER, live from Milan:

- EMO Milan teaser video

- EMO Milan, Day 1: The new Aries NGP+ masters big grinding tasks

- Don’t miss EMO Milan Day 3: World Premiere Grinding Machine

Visit us in Milan, Hall 2, Booth D06

News overview

Categories

All posts

- More than 30 years of full dedication - Rolf Herrmann looks back on his time as subsidiary manager and technology enthusiast at SCHNEEBERGER USA

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.