SIG-TECHNIK sharpens hobs with SCHNEEBERGER Technology

SIG-TECHNIK Werkzeug GmbH in Grebenstein looks back on over 30 years of experience in the field of cutting tools. Through continuous development of machine technology and grinding processes, SIG has been able to establish a leading reputation in the manufacturing of form tools. A second important pillar of the company is the reconditioning of gear cutting tools, such as hobs as well as standard cutting tools, step drills and milling cutters.

For almost 20 years, SIG has been using the proven grinding technology of J. SCHNEEBERGER Maschinen AG. It all started with a Gemini MRG, which was followed by a Corvus GDS. The Corvus is capable of grinding long tools with large diameters.

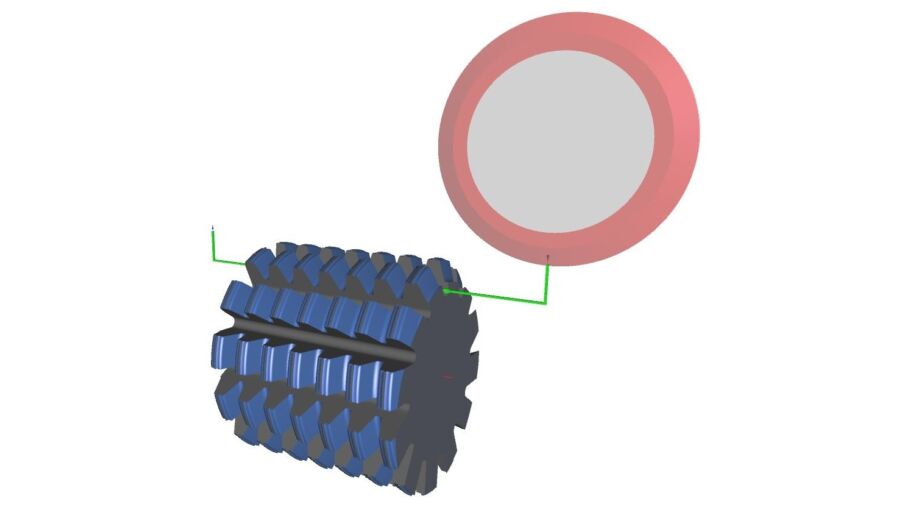

To benefit from the latest state of technology, a Norma NGC 750 was recently purchased. With its extended X-travel of 750 mm, it is the big sister of the standard Norma NGC (470 mm). With the very compact machine dimensions, the regrinding of larger hobs would hardly been possible with any other machine. Furthermore, the new addition to the SIG range of machines is equipped with a machine-integrated loader (MIL), which is used to sharpen standard tools in an unattended shift.

The Norma NGC 750 can be used for the production of complex special tools. The modern CAD/CAM software Qg1, a development by SCHNEEBERGER, allows meeting their customers ever-increasing demands. All common grinding applications are predefined in the extensive tool database TOOGLE. Customer-specific profiles can be easily produced using the DXF interface. Qg1 supports the employees with extensive simulations and parameter-related help pictures during development.

In Qg1 the simulation of the geometric tool model, the grinding process as well as the machine simulation including safety-relevant collision monitoring are available.

The current production and grinding process can be monitored directly at the machine. Parallel to grinding, the next tool can be edited thanks to software multitasking. This proves to be a convenient and productive function in the daily use of the machine.

SIG-TECHNIK Werkzeug GmbH completes the cutting tool service for high customer satisfaction with competent advice, short delivery times and sophisticated quality assurance. SCHNEEBERGER is pleased to be part of the long-standing cooperation.

Matthias Prinz, J. SCHNEEBERGER Maschinen GmbH

Categories

All posts

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- Reading tip: FORUM article on automation solutions for modern CNC grinding machines

- BRIANI and SCHNEEBERGER, a 30-year exemplary Collaboration for the Italian Tool Industry

- CCTV Business Report about Magally Technology reaches Millions of Viewers

- Turning the tides by going full CNC and automation in carbide insert production