Extended STEP Interface in Qg1

Our own STEP* interface in our grinding software Qg1 has already been presented many times at trade fairs, to our visitors in-house, and our numerous representatives.

Extended functions are now available that make the possibilities even more exciting.

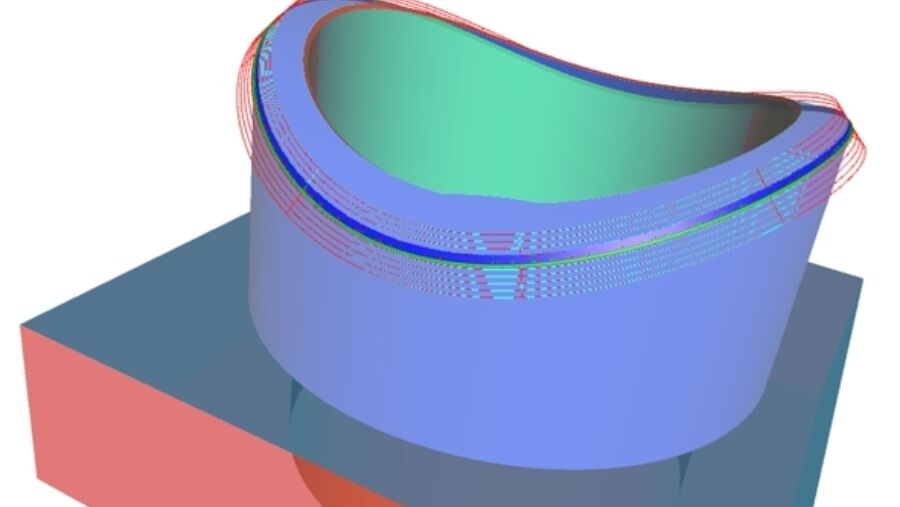

Let’s examine a cylinder with a corrugated cut, where the corner bevel needs to be ground. Without 3D capability, this is no simple endeavour, especially if the cut features asymmetry.

No more than three steps are needed to get this done:

After importing the STEP model, you select the surface or edge to be processed, which in this case is the outside bevel.

You can select whether the bevel is processed completely or only a segment of it should be processed. As required, the surface may be extended further, either in the direction of the surface normal or at an angle to it. This is also possible without any problems, no matter whether the original model delivers this information or not.

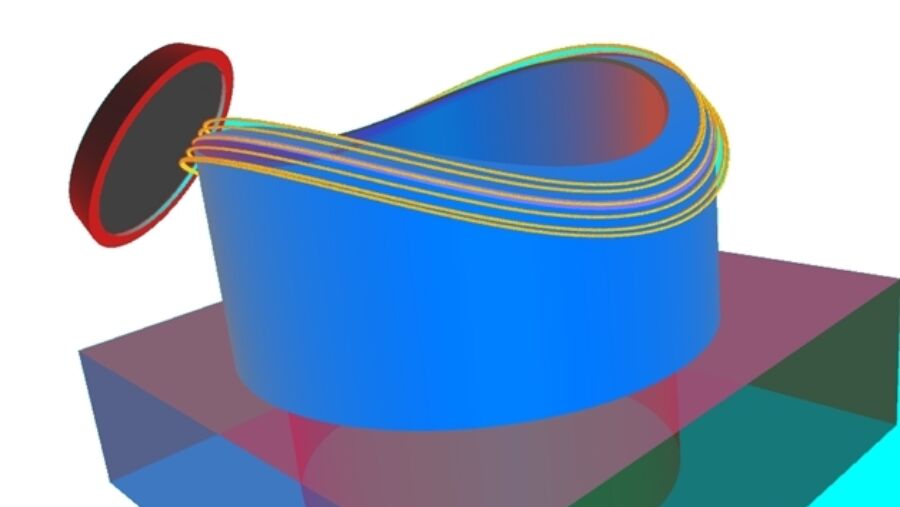

Next, just select the matching grinding wheel for this, and the program is finished.

In the figure (Fig.2), the extended projection features 5 edges, which follow the grinding wheel. The STEP interface already offers several automated grinding processes like cylindrical grinding, cone grinding, and edge extrusion. If the whole thing is connected with Qreator, then there’s practically no limit to the possibilities.

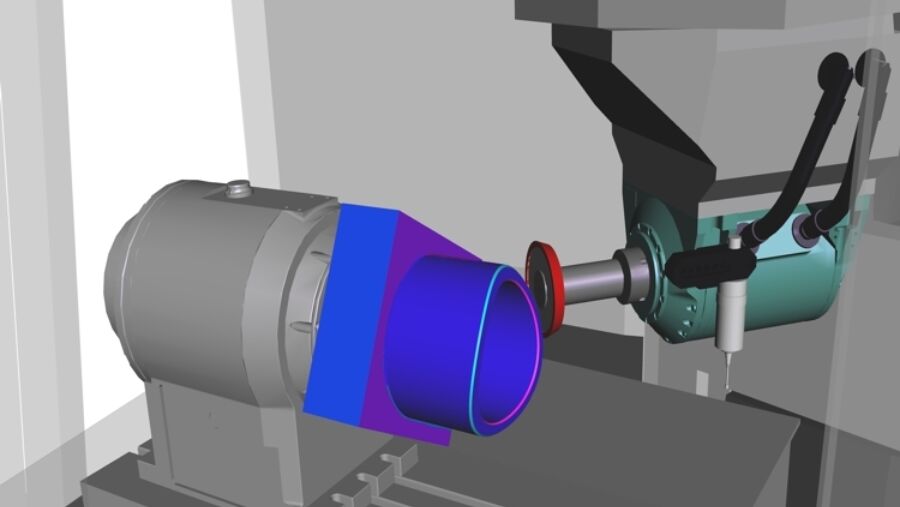

For an encore, a large part of the STEP grinding programs can be simulated in the new machine simulation, including the component and grinding wheel. The integrated time calculation also enables the processing duration of the component to be specified very precisely.

Categories

All posts

- Fresh & Sharp in Quinto Qg1, release 2025-04

- Fresh & Sharp in Quinto Qg1, release 2024-09

- SCHNEEBERGER once again climbs the Mount Everest of grinding: Carbide Power Skiving Cutter Module 0.17 in the highest precision class

- The American Metalworking Community met at IMTS 2024; where SCHNEEBERGER presented the latest trends in CNC grinding technology

- IWF Atlanta 2024: Corrugated Knives, Woodworking Inserts and more with Qg1 and SCHNEEBERGER