Gear Milling Cutter production, logarithmical back relieve grinding

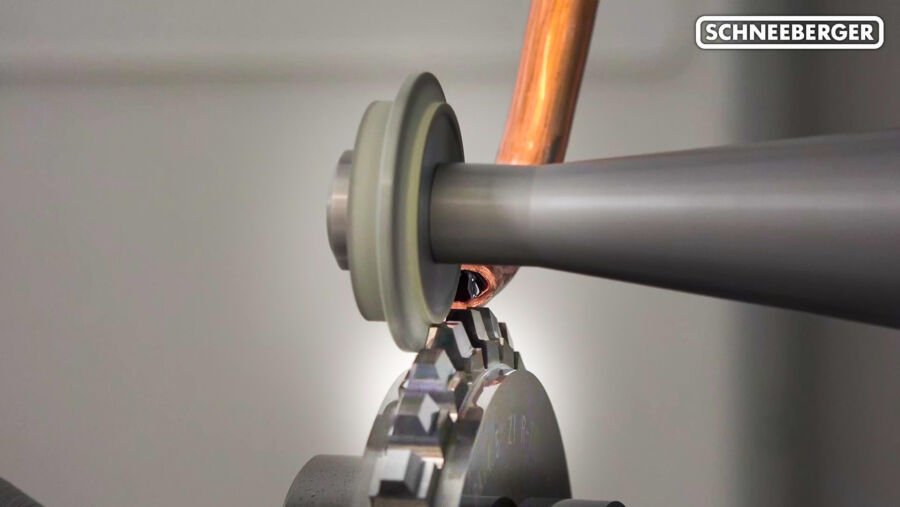

The universal 5-axis tool grinding machine Gemini NGM Linear produces, in addition to high-performance round tools, gear milling cutters with the highest accuracy requirements in carbide or HSS.

Gear Milling Cutter production, logarithmical back relieve grinding

Gear milling cutters required for the production of worm shafts and gears, pinion gears and racks are produced on the Gemini NGM Linear. The profile is logarithmically back relief ground with a small grinding wheel (collision avoidance with follow tooth), and up to module 22 is possible. The Qg1 software covers all known worm cutter and module cutter types and shapes.

The production of gears by milling without finishing is an extremely efficient method, especially popular in the automotive industry. In this case the milling process provides the final gear geometry, consequently the cutting tool must meet the highest AAA quality criteria. The Gemini NGM reliably achieves this thanks to linear drives technology, sophisticated thermal stability and rock-solid structural mechanics.

Categories

All posts

- SCHNEEBERGER once again climbs the Mount Everest of grinding: Carbide Power Skiving Cutter Module 0.17 in the highest precision class

- The American Metalworking Community met at IMTS 2024; where SCHNEEBERGER presented the latest trends in CNC grinding technology

- SCHNEEBERGER GrindingHub Highlight 7/7: Maximum precision and productivity with the new Gemini NGM GHP, the Gear Hob Profiling Machine

- SCHNEEBERGER GrindingHub Highlight 6/7: High-End Components Manufactured with the Norma NGC

- SCHNEEBERGER GrindingHub Highlight 5/7: Norma NGC Scara, The Gear Cutting Tool Powerhouse