NEW: The SCHNEEBERGER Corvus NGB 4’500, the CNC grinding machine with 4.5m (177”) travel.

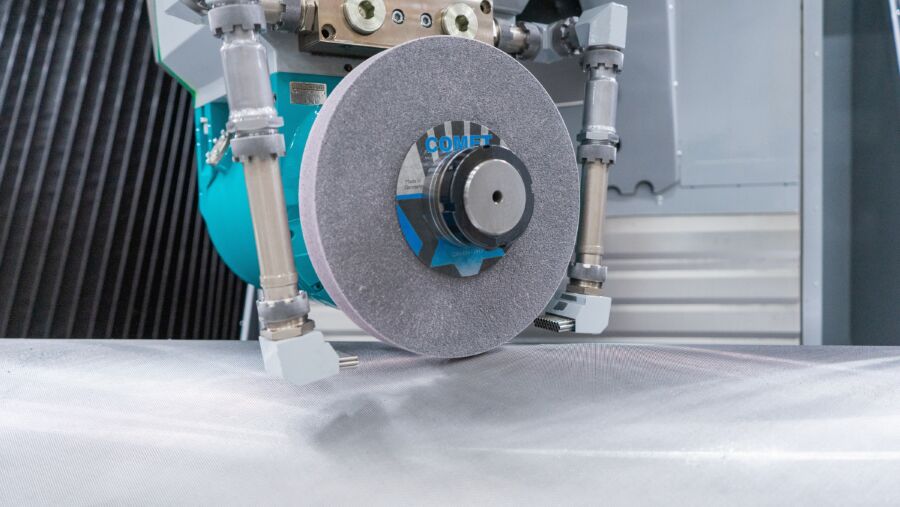

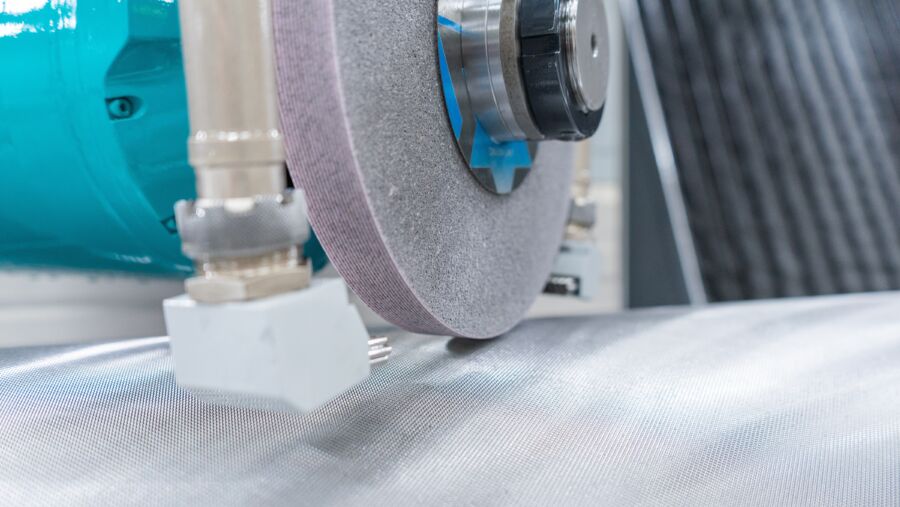

The longest version of the legendary Corvus NGB 5-axis grinding machine opens doors to applications in new dimensions: Precision shafts with splines or threads, splined shafts, camshafts, extruders, embossing rollers and XXL cutting tools. Everything that is large, certainly also heavy and always high-precision ground.

The latest addition to the J. SCHNEEBERGER Maschinen AG product range is designed for large grinding jobs. With years of know-how in the construction of traveling column machines and their diverse range of applications, there had to be a natural evolution: A machine even bigger and even stronger than the four smaller Corvus sisters.

5-axis CNC grinding of parts over 4 m long is a novelty. What is otherwise only produced labor-intensively on 4-axis cylindrical or surface grinding machines can now be machined in one clamping with higher production complexity. Threads, Flutes and Profiles require 5-axis technology.

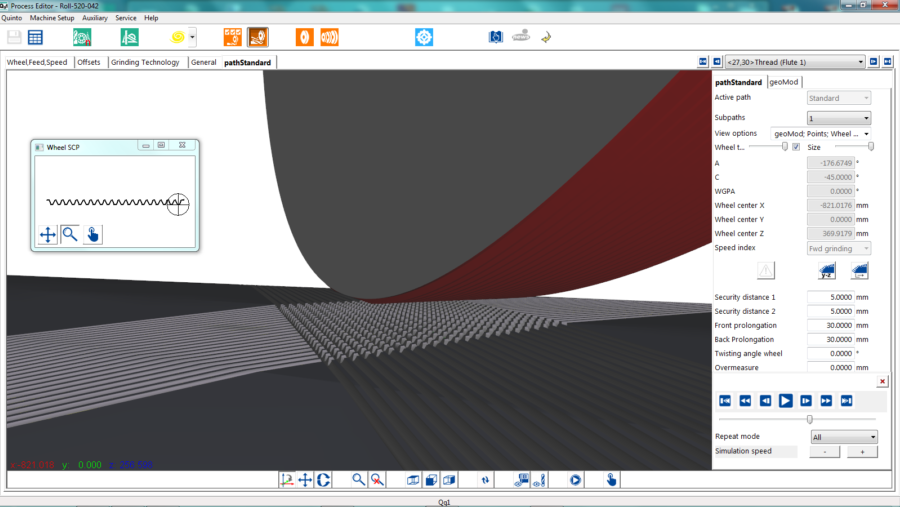

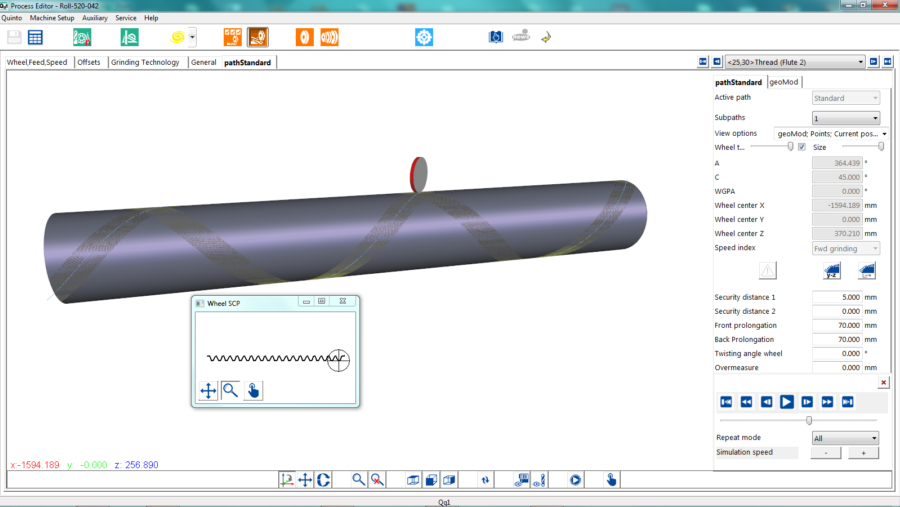

The experts of SCHNEEBERGER grinding technology and their preferred CAD/CAM software Qg1, have experience in 5-axis grinding - regardless of part size. The 3D representation of parts, grinding processes and machine simulation are scalable. Well-known features such as 3D import, automatic calculation of form wheels and clearance grinding are also in demand for large-part production.

Specifications of the new Corvus NGB 4’500:

- Center distance and max tool length 5.1m/200”, diameters up to 600mm/23.5” and up to 7t max weight.

- A T-slotted tool table of 6.7m/263.7” length

- Chucking options for large tools such as A-axis, support bearings with 4jaw chucks, magnetic plates and steady rests.

- Work travel: X 4500mm, Y 400mm, Z 400mm, A, B, and C 360° each.

Proven technology for the Corvus type machine:

- Corvus conform a solid machine design. Adapted to the new dimensions results in 44 ton of the most advanced machine designs.

- Perfect machine kinematics for every application: Swiveling spindle axis as version B- or C-axis.

- Dynamic and precision: Linear motor (optional) and high precision direct scale feedback.

- Large selection of wheel spindle power with continues power from S1 to 30kW and high frequency spindles up to 60’000RPM

- A-axis direct drive motor with 1200Nm torque.

- The Corvus NGB machine is available in in five different lengths: 850, 1’250, 2’100, 3’100, new 4’500mm in X.

Do you have the right job for the new Corvus NGB 4'500? We will be happy to advise you: Contact your nearest SCHNEEBERGER sales engineer or representative.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability