Live from EMO Milan, Day 5: The Master Exam of Precision Parts Grinding

All-in-one and all in top-notch precision: M24 thread, hexagon, cylindrical grinding, eccentric grinding, spline and eccentric ball nose

The Master Exam of Precision Parts Grinding, live at EMO 2021

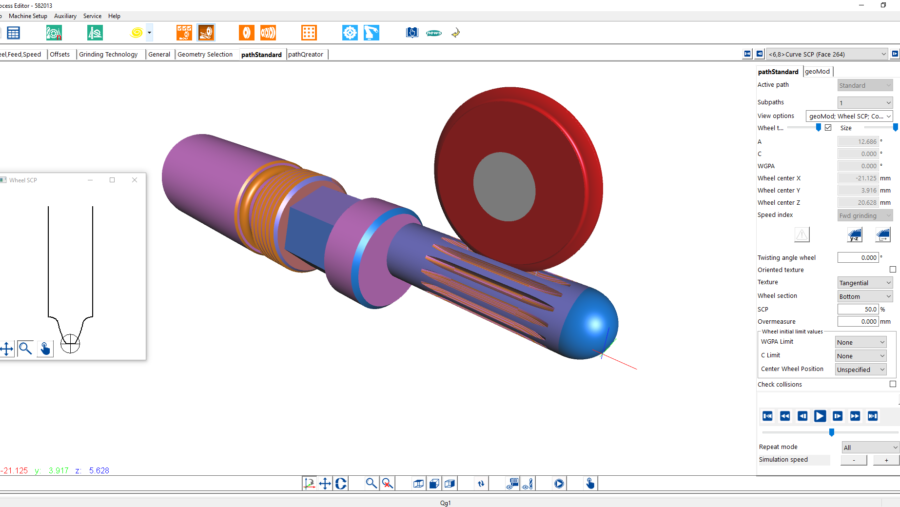

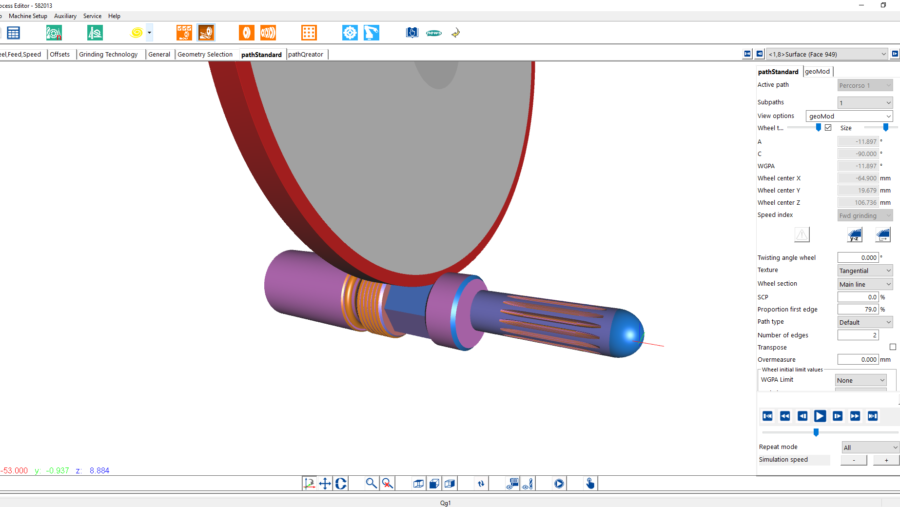

With Qg1, advanced grinding projects can easily be programmed thanks to 3D-file import. There are no limits in mastering complex geometries and it offers outstanding process capabilities.

The right software to speed up your process from part design to production.

The Gemini NGM reliably achieves outstanding results thanks to linear drives technology, sophisticated thermal stability and rock-solid structural mechanics. A wide range of accessories such as wheel loader, Fanuc robot, dressing unit and the right spindle for the specific application are available. Here at EMO, the Gemini NGM is equipped with a 24kW (S1) spindle and a 60’000 rpm high frequency spindle for spline grinding applying a Ø22 mm wheel.

Learn more about SCHNEEBERGER´s powerful production machine, reading the independent test report: Machine check, Gemini NGM on the test bench.

Stay tuned with SCHNEEBERGER, live from Milan:

- Teaser video of EMO Milan

- EMO Milan, Day 1: The new Aries NGP+ masters big grinding tasks

- EMO Milan, Day 2: Skiving Cutter Profiling on Sirius NGS

- EMO Milan, Day 3: Norma NGC, the best-seller from SCHNEEBERGER, now with Scara robot

- EMO Milan, Day 4: The brand new SCHNEEBERGER NGV900 oil filtration and temperature control system

Visit us in Milan, Hall 2, Booth D06.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability