SCHNEEBERGER grinding technology at CIMT 2025, the biggest machine tool show worldwide

The exhibition of superlatives: 17 large exhibition halls, 310’000 m2 and more than 2’800 exhibitors. The modernized Capital International Exhibition Center of China has doubled its space and already filled it to full capacity at this year's CIMT. Cutting tools in all variations played an important role and SCHNEEBERGER was right at the center of the action.

Broach production & sharpening companies nationwide use SCHNEEBERGER Corvus. Mrs. Liu knows them all.

Mr. Tao consults on choosing the right equipment to grind gear hobs, shaper cutters, skiving cutters, stick blades, bevel gear cutters…

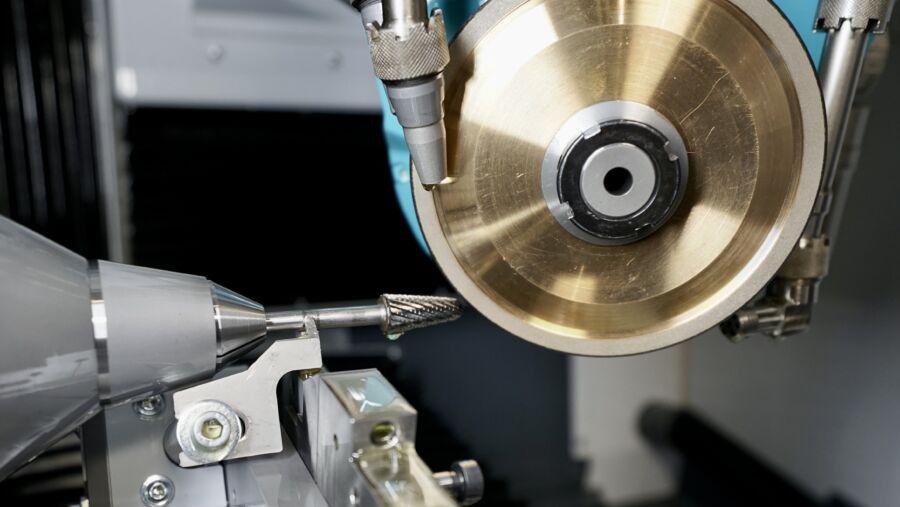

Sirius NGS has proven its leading position in profile insert grinding, thanks to its rock-solid structure, all linear driven axes and HSK80 interface motor spindle which supports wheels of diameter up to 300mm. CAD/CAM-software Qg1 with Toogle database presents an “easy access pass” for newcomers in profile insert grinding. It realizes all types of high-precision inserts, such as threading, grooving, various gear cutting inserts, as well as drill tips.

Aries NGP demonstrates its capability in terms of productivity and flexibility in solid carbide tools grinding and fastest robot loading ever. This small footprint machine, including filtration system, temperature control and mist collector, is a complete grinding center. On top of that, Aries NGP creates enthusiasm: One machine has been spotted, ordered and delivered directly from SCHNEEBERGER’s exhibition booth.

The highly motivated team of SCHNEEBERGER Nanjing will be happy to assist in all matters of 5-axis grinding technology. Our skilled engineers have extensive experience in cutting tools, forming tools and precision part grinding.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability