6-axis kinematic for the production and profiling of all types of broach tools

Optionally available concentricity function with torque up to 1250 Nm

Thanks to the 1250 mm to 3100 mm X-stroke, the largest of tools can also be processed.

Grinding spindle power 46 kW peak, highest power for the production of large tools with high chip volumes

Recirculating ball screw or highly dynamic linear motors

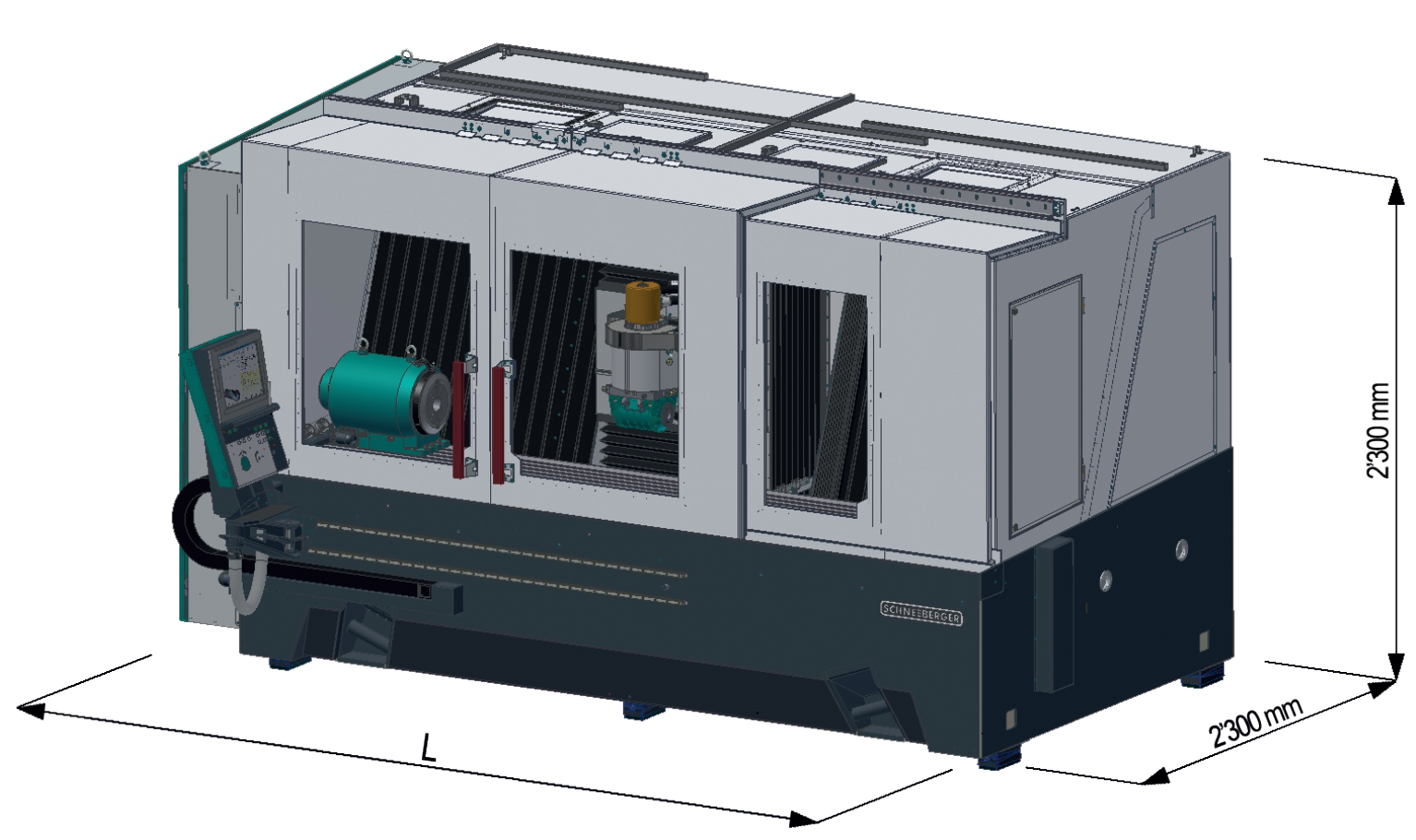

corvus NGB BBA

Production and regrinding of all known broaches with the 6-axis CNC grinding machine.

The 6-axis CNC grinding machine corvus BBA with its well thought out, attractive design is the leader in broach grinding machine. It is the result of years of co-operation with broach tool manufacturers from all over the world. The CNC grinding of broach tools is possible in a single clamping grinding gullets, spiral flutes, profile, spiral profile, clearance angle, chamfers, cylindrical grinding or surface grinding and all with the highest precision. Complete processing OD and face, up to 2800 mm cutting length, diameter up to 400 mm, maximum workpiece length that can be clamped 3500 mm. With its T-slotted table, the machine envelope can accept steady rests, tailstocks and magnetic chucks.

In all likelihood, the following broach tools and broach needles are ground the world over on a corvus BBA:

- Internal broach tool: Profile broaching tool, round, polygonal, rectangular, hexagonal, keyway, feather key groove

- External broach tool: Flat broaching tool, concave tool

- hard broach tool

- Large tool

- Turbine tool

- Helical fluting tool

- Broach needle for twist broaching

- Broach needle for hard broaching

- Gear rack broach needles

- Custom broach tools

Thanks to an A-axis torque of up to 1250 Nm, tools up to 1500 kg can be produced or re-ground. Transmission manufacturers appreciate the universal nature of this machine when regrinding of gear cutting tools such as gear hobs and shaper cutters.

Accessories for individual expansion of the application spectrum and increased productivity:

- X-stroke of 1250 mm up to optional 3100 mm

- Measurement system in all axes

- Linear motors in all axes

- Direct drive motor for cylindrical grinding tasks up to 1250 Nm torque

- Dressing unit for dressing profiles

- Manual or hydraulic tailstock

- Steady rest

- Magnetic chucks

- Collet chucks, clamping mandrels

- Coolant filtration system

- Exhaust air filter

- CO2 extinguishing system

Applications

Video

Technical data

Axes:

X: 1250, 2100, or 3100 mm longitudinal axis, linear motor, resolution 10 nm

Y: 400 mm, transverse slide, recirculating ball screw or linear motor, resolution 50 nm or 10 nm

Z: 400 mm, vertical axis, recirculating ball screw or linear motor, resolution 50 nm or 10 nm

A: ∞ ISO 50 tool carrier, resolution 0.0001°

C: 365°, rotation of the grinding head, resolution 0.0001°

BC: 290°, rotation of the grinding head, resolution 0.0001°

Control:

FANUC 31i-B5, 6 controlled axes

19” TFT color monitor with touch screen, USB 3.0

Grinding head:

Double ended grinding spindle with direct drive, water cooled

10 kW (100 %), 13 kW (60 %) for grinding wheels ø 30 mm to ø 250 mm, 1000 to 12,000 rpm, HSK 50

Weight:

X-stroke 1250 mm: L 3285 mm, weight 13,500 kg

X-stroke 2100 mm: L 4135 mm, weight 17,000 kg

X-stroke 3100 mm: L 5365 mm, weight 20,500 kg

Dimensions

X-stroke 850: L 2885 mm, weight 12,000 kg

X-stroke 1250: L 3285 mm, weight 13,500 kg

X-stroke 2100: L 4135 mm, weight 17,000 kg

X-stroke 3100: L 5365 mm, weight 20,500 kg