A μ-sized nip in the middle of the tool decided the GrindTec Challenge

The live finale of the "Tool Grinder of the Year" competition offered more than any James Bond thriller - suspense, emotion, action - plus immense know-how at the cutting edge of technology.

The winners of the GrindTec Challenge "Tool Grinder of the Year" (from left): Fernando Carrascosa Santos and Armin Reich (joint 3rd place), Maximilian Ullermann (2nd place), Felix Conrad (1st place).

from Tilo Michal

The competition "Tool grinder of the year", which is well established at the GrindTec by now, was decided this time with a kind of photo finish - that's what you would call it in top-class sports. What the finalists have achieved at the GrindTec Challenge can unquestionably be described as Olympic. The "Tool Grinder of the Year" award has been offered by the publishing house MI Connect (formerly Moderne Industrie, , established among others with the industry magazines "Produktion" and "Fertigung") at the GrindTec for many years. Premiere: In 2022, for the first time, the final of the competition could be held simultaneously on identical precision grinding machines from SCHNEEBERGER, on which the two finalists competed directly against each other.

In the finale, things first go "in synch", because finalist Maximilian Ullermann needs much longer to program the SCHNEEBERGER Aries NGP than competitor Felix Conrad, who has already been on the move with the Aries NGP for minutes. Then everything turns around: Conrad stumbles, having to manage a collision between chuck, tool and machine. Machine stop, new setup, program check, and continue. Meanwhile, Ullermann is also on the move, and then both machines are running at high speed - it's a head-to-head or rather a spindle-to-spindle race. Of course to ensure that everything goes according to plan, the two judges of the competition are also on site, Olivier Pellegrini from SCHNEEBERGER and Andreas Grabmeier, owner of Grabmeier GmbH in Augsburg, who himself won the prestigious prize in 2010, as well as SCHNEEBERGER machine instructors Noel Geiger and Hans Bietenhader. The finalists stand only about six meters back to back from each other;. But naturally, they keep looking over their shoulders: What is the other one doing?

How did the two get this far?

The competition consists of two parts. The first part is about the theoretical basics that a tool grinder must have these days: Knowledge of materials and tools, technology and processes. In addition, questions about a work-piece have to be answered. It is important that each participant solves the questions alone. The answers, which are checked by a jury of experts, decide which candidates are allowed to take part in the finals "Tool Grinder of the Year". The finals - part two of the competition - will take place at the GrindTec 2022 in Augsburg.

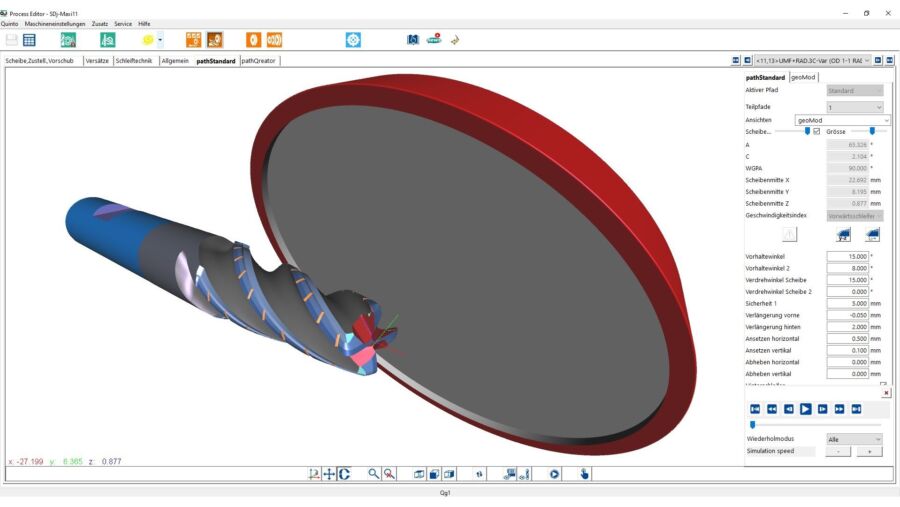

In an exciting "everyone against everyone" and "everyone against the clock" competition, the last-place finishers in the preliminary round must program and machine a specific work-piece on a grinding machine. The winner and thus "Tool Grinder of the Year 2022" is whoever produces the best work-piece in the shortest amount of time. In order to ensure a level playing field, all finalists were instructed for two days on the actual competition grinding machine a few weeks earlier at the J. SCHNEEBERGER Maschinen AG training center in Roggwil, Switzerland. However, at the same time, the theoretical knowledge is tested again in this part of the competition: Cheating when filling in the questionnaire in the theoretical part of the test is therefore pointless. In the first GrindTec final round with five participants in Augsburg, the finalists each produce a tapered finishing end mill with four cutting edges, two of which are center cutting, and of course right at the show.

In addition, a Weldon flat has to be ground on the tool shank using STEP import. Afterwards, the tools will be evaluated by the expert jury and the two best participants will be selected for the final. "Tool grinder of the year" will be whoever produces another tool here in the highest quality and in the shortest time.

Finale with Finesse

The final challenge was to program and grind an HSS end mill with four cutting edges and a center cutting edge manufactured on a SCHNEEBERGER Aries NGP and live and in front of the interested trade show audience. A few minutes after the two finalists get going, they are tied. An interested crowd of young grinders, press representatives, trade show visitors and board members of the professional sponsor of the GrindTec, FDPW, surrounded the two candidates. They now have to manage the situation, stay cool and continue with grinding.

A hectic situation, the professionals of the industry in your back, a total roller coaster of emotions. The tension increases from minute to minute. And then, a few minutes later, virtually at the same time, Ullermann and Conrad are finished, the photo finish! At this point, however, no winner has been determined; the jurors first have to inspect the presented work in detail.

The runner up Finalist gets deduction for a minimal inaccuracy. "We are always refering to μ here," emphasizes Editor-in-Chief Claus Wilk of MI Connect in his presentation a few hours later in the evening.

In Win on a μ-Scale.

"In the end, we could only determine the winner through an intensive analysis of the two competing workpieces. Maximilian Ullerman, who initially had to catch up, still had a minimal nip in the μ-size range in the center of the work-piece that was higher than the outside diameter. A groove that could make minimal scratches. Normally, this is not a problem because the work-piece can still be reworked. Under competitive conditions, however, there was no tolerance for this," summarizes juror Andreas Grabmeier.

The final of the Tool Grinder of the Year 2022 was therefore won by Felix Conrad with a μ-thin lead over Maximilian Ullermann. Third place goes equally to Fernando Carrascosa Santos and Armin Reich, combined with a hearty congratulations from SCHNEEBERGER. The Aries NGP CNC grinding machines proved their strengths in the competition under competitive conditions. The Aries NGP type used is SCHNEEBERGER's most compact 5-axis grinding machine, ideal for regrinding tools and, thanks to the integrated robot, suitable for the efficient production of small and medium batch sizes. All this realized on the footprint of a tool cabinet.

Big Celebration for the Winner.

On the evening of the third day of the trade show, an short awards ceremony followed in the FDPW Forum; the industry representatives celebrated the award winners with enthusiastic applause. The moderation was taken over by Claus Wilk from MI Connect, who as the master of ceremony led through the program. "The excitement, the sizzle, the cheering along, the close nit grinding community, I found it to be something very special. I really enjoyed this day and really enjoyed hosting. I take a lot away from it." There have been generous travel arrangements for all finalists, as well as generous prizes. "Whoever made it to the finals here probably doesn't have to worry about their professional future," was the credo of the presenter as well as the enthusiastic audience.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability