Live from the GrindingHub, Day 3: Grinding of precision components with Qg1!

SCHNEEBERGER has a name in the grinding of precision components. With new features of the Qg1 grinding software, all geometries beyond conventional tool types can easily be implemented.

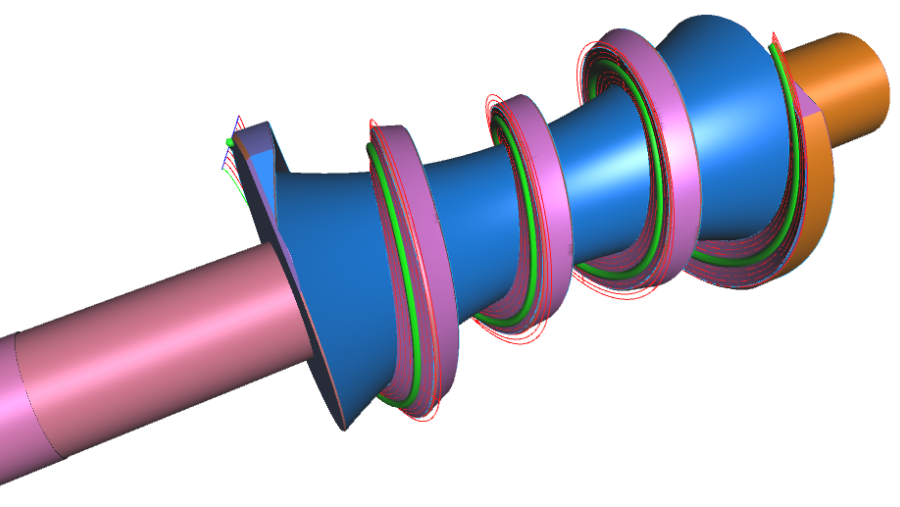

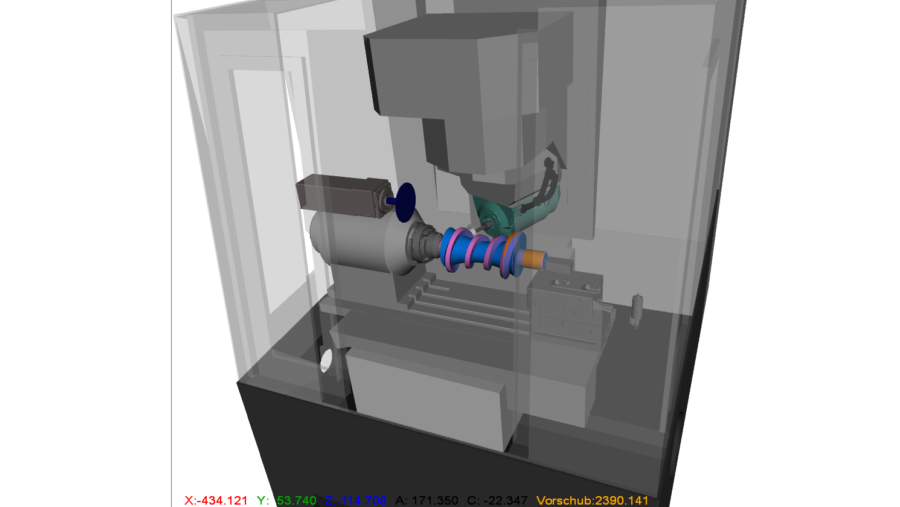

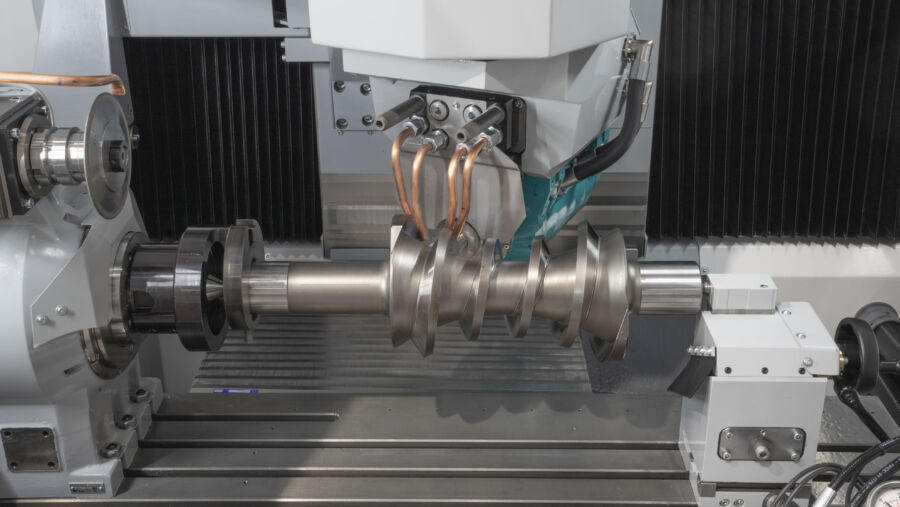

The duo Norma NGC and Software Qg1 demonstrates its capabilities in grinding of a roller worm shaft. For globoidal cams, the precision requirements are enormous, with maximum flexibility, small batch sizes and a wide variety of geometries.

The programing of the grinding process is entered completely and directly via the SCHNEEBERGER Qg1 grinding software. A 3D model from the customer's designers serves as the basis, which can easily be imported via the Qg1 interface. With just a few clicks, the surfaces to be ground are selected and individually suitable grinding processes are assigned. Wheel forms are automatically calculated and dressed to shape with the CNC dresser.

The universal grinding machine SCHNEEBERGER Norma NGC with X-travel 750 mm grinds impressively large workpiece dimensions. Individual setups are possible on the generously designed T-slot table. The modular selectable SCHNEEBERGER setup leaves nothing to be desired: wheel changer, work piece loader, dresser, cylindrical grinding head, work piece and wheel probe, direct scale in all axes, grinding oil filtration with chiller system.

Stay on it with SCHNEEBERGER, live from Stuttgart, Hall 10, Booth D30.

Categories

All posts

- Happy Holidays

- INSAM EWALD & SCHNEEBERGER: Tradition and progress in harmony

- At Motion & Power Technology Expo 2025, the American gear manufacturing community came together as SCHNEEBERGER showcased the latest innovations in CNC grinding technology

- EMO 2025 - Thank you very much for visiting SCHNEEBERGER.

- EMO NEWS 4/4: The latest generation of SCHNEEBERGER steady rests gives the Aries NGP additional production stability