Spindle power 46 kW peak

Optionally available cylindrical grinding function

Automatic grinding wheel changer for grinding wheel package with coolant nozzle

Machine-integrated loader with a 300 x 300 mm pallet

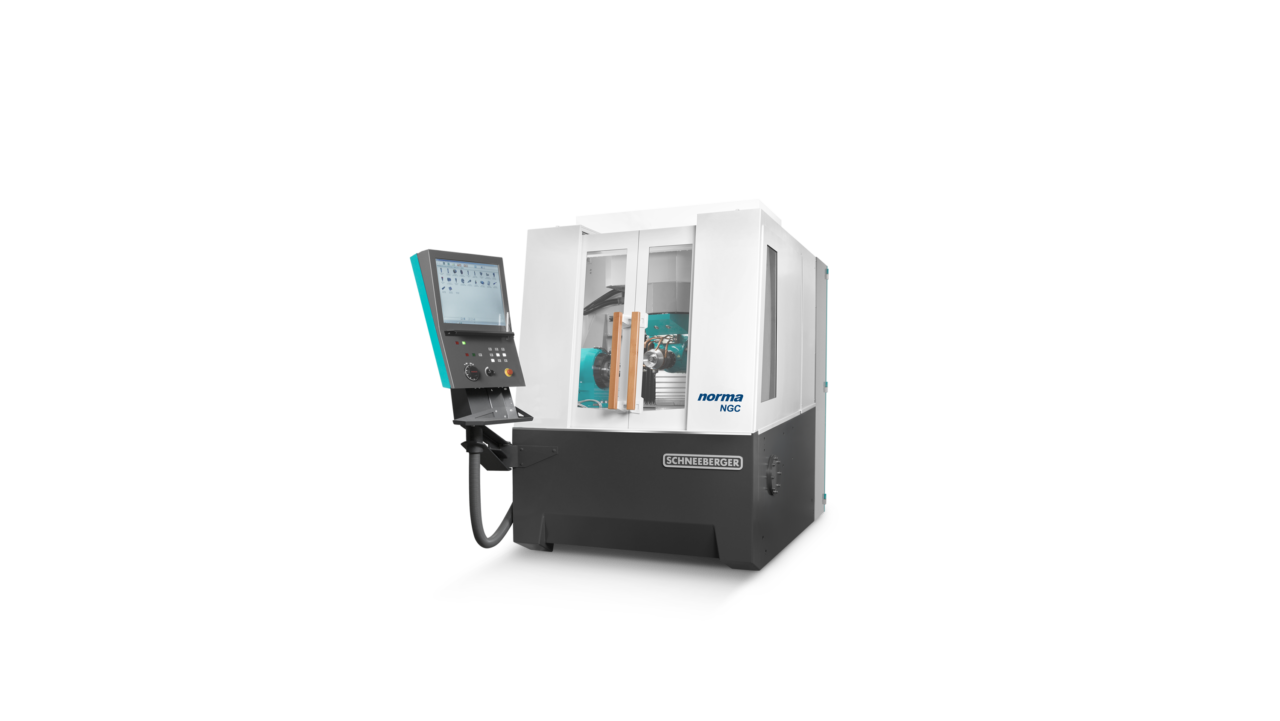

norma NGC

Universal and compact 5-axis CNC tool grinding machine designed for the production and regrinding of end mills, drills, profile tools and the servicing of gear cutting tools.

The normaNGC is the universal 5-axis CNC tool grinding machine for the production and regrinding of cutting tools. Complete processing around OD and face, up to 300 mm cutting length, diameter up to 400 mm, maximum workpiece length that can be clamped 500 mm.

Cutting tools such as end mills, ball nose cutters for mold making, high-performance drills, reamers, profile end mills, indexable profile inserts in HSS, carbide gear cutting tools.

There are specific software, grinding processes and clamping systems for regrinding gear cutting tools, end mills, pinion cutters and bevel gear cutters.

Production grinding of knives for the paper, food and plastics industries. Wheel-shaped workpieces with special clamping and automatic loading.

Accessories for individual expansion of the application spectrum and for increasing productivity. Numerous accessories to expand the application range and productivity of the machine.

- Workpiece loader

- Grinding wheel pack loader

- Measurement system in all axes

- Manual or hydraulic tailstock

- Manual, hydraulic or CNC controlled steady rest, following the grinding point

- Collet system, clamping mandrel, indexable tool holder

- Coolant filtration system

- Exhaust air filter

- CO2 extinguishing system

Applications

Video

Technical data

Axes:

X-axis: 470 mm, Longitudinal slide, roller guide, ground recirculating ball screw, resolution 50 nm

Y-axis: 390 mm, Transverse slide, roller guide, ground recirculating ball screw, resolution 50 nm

Z-axis: 325 mm, Vertical column, roller guide, ground recirculating ball screw, resolution 50 nm

A-axis: ISO 50 tool carrier, resolution 0.0001°

C-axis: 380°, Rotation of the grinding head, resolution 0.0001°

Control:

FANUC 31i-B5, 5 controlled axes

19” TFT color monitor with keyboard and touch screen, USB 3.0

Loader:

Integrated parts loader, tool pallets 300x300 mm

Disc loader with 7 positions, 21 grinding wheels

Grinding head:

Double ended grinding spindle, direct drive, HSK 50

10 kW (100 %), 13 kW (60 %) for grinding wheels ø 40 mm to ø 250 mm, 1000 to 12,000 rpm, liquid-cooled

Weight:

5000 kg

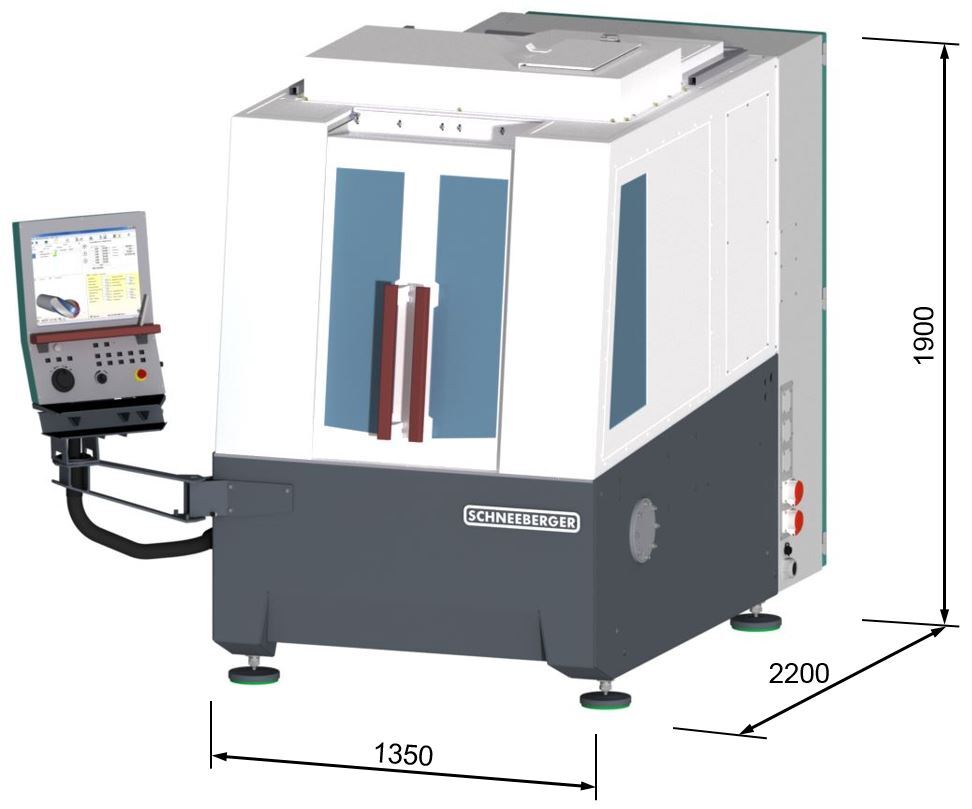

Dimensions