Live from GrindTec, day 2: Gemini NGM as you've never seen it before!

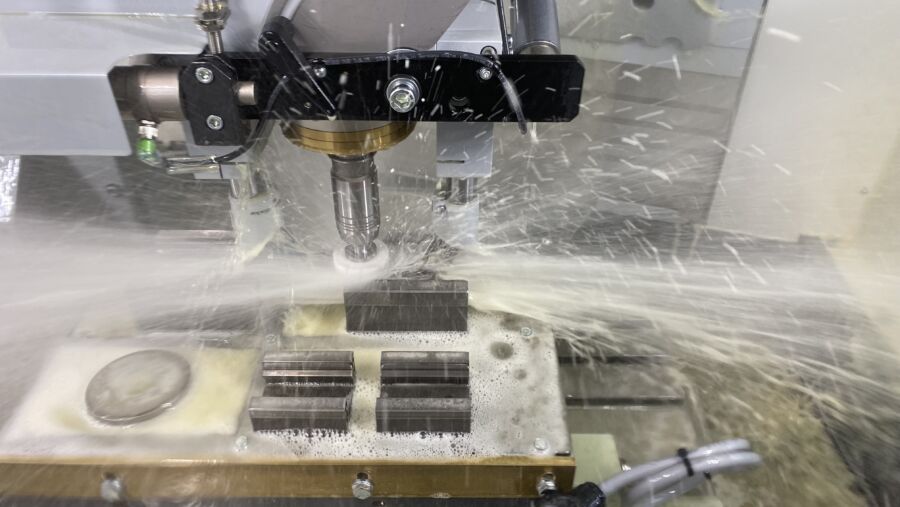

The new profile grinding machine based on Gemini NGM Linear achieves top class accuracy. Thereby a new field of applications gets access to SCHNEEBERGER technology.

Linear guides are optimized for high rigidity at low-friction for loads ranging from a few grams to several tons. To achieve a perfect fit between the guide and the runner block, profiling must be done with extreme precision. The manufacturing solution comes in the form of Gemini NGM profile grinding edition: Rigid kinematics, X-, Y- and Z- linear drives and a 40’000rpm high-frequency spindle.

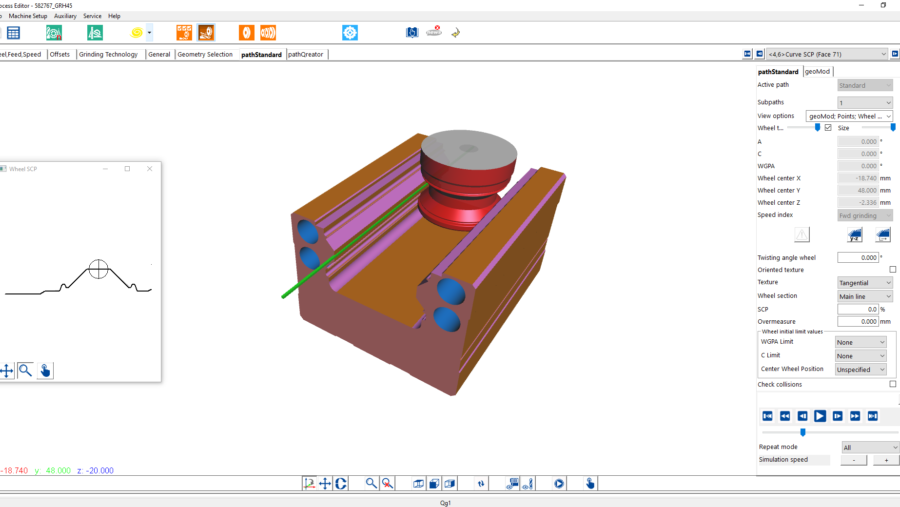

Thanks to the Qg1 CAD/CAM, programming is done in two simple steps: import of a 3D model and selection of the surface to be ground. The shape of the grinding wheel is automatically calculated and dressed on board the machine.

The new Vasca NGV900 is in charge of perfect temperature stability. Two separate circuits for process and motor cooling keep the machine precise. The multi-stage filtration consists of an automatic magnetic separator, paper filter and 10 and 5 micron cartridge filter.

For high precision applications, SCHNEEBERGER has the right solution!

And the show goes on, stop by and visit us at GrindTec in Hall 3 Stand 3096. Stay tuned with SCHNEEBERGER News.

Categories

All posts

- Fresh & Sharp in Quinto Qg1, release 2025-04

- Fresh & Sharp in Quinto Qg1, release 2024-09

- SCHNEEBERGER once again climbs the Mount Everest of grinding: Carbide Power Skiving Cutter Module 0.17 in the highest precision class

- The American Metalworking Community met at IMTS 2024; where SCHNEEBERGER presented the latest trends in CNC grinding technology

- IWF Atlanta 2024: Corrugated Knives, Woodworking Inserts and more with Qg1 and SCHNEEBERGER