SCHNEEBERGER NEWS

The latest trends from the world of 5-axis CNC grinding

New features of the CAD/CAM software Qg1, further machine development, customer reports and background information. All of that, only in SCHNEEBERGER NEWS.

Live from EMO Milan, Day 4: The brand new SCHNEEBERGER NGV900 oil filtration and temperature control system

The new Vasca NGV contributes significantly to the thermal stability of grinding machines, demonstrated at EMO on two high performance grinding machines. Both, the Sirius NGS and Gemini NGM produce real tools and precision parts at the show.

Read moreLive from EMO Milan, Day 3: Norma NGC, the bestseller from SCHNEEBERGER, now with Scara robot

World first at EMO 2021, Norma NGC with Scara robot automation. The double gripper loading of shank tools or precision parts takes 10 seconds only. The capacity of two pallets makes is it the perfect machine for production or professional sharpening.

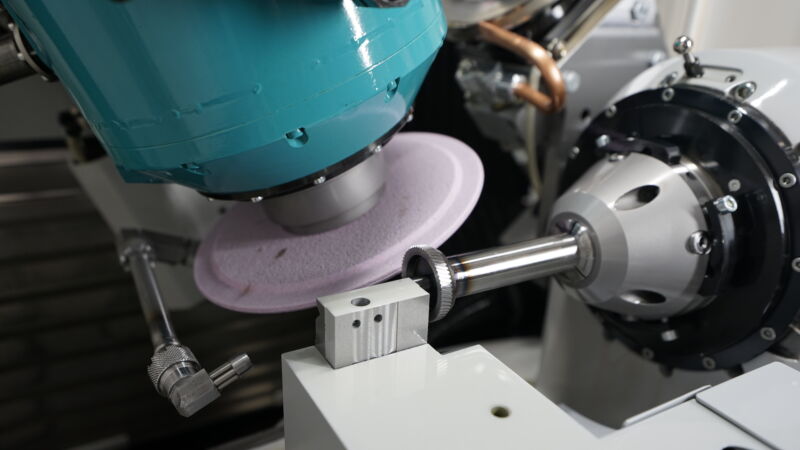

Read moreLive from EMO Milan, Day 2: Skiving Cutter Profiling on Sirius NGS

SCHNEEBERGER makes it happen at the show: Production of skiving cutters in highest precision, efficiency and even with full robot autonomy

Read moreLive from EMO Milan, Day 1: The new Aries NGP+ masters big grinding tasks

Aries NGP+, the enlarged version of SCHNEEBERGER’s compact 5-axes CNC grinding machine, is designed to achieve great things. Sharpening a Ø380 bevel gear cutter is an impressive demonstration of its capabilities.

Read moreEMO Milan, the SCHNEEBERGER technology hotspot

Four grinding technology attractions have been waiting for their grand entrance. Now the time has come: Clear the stage for skiving cutter mass production, precision components based on 3D file import, robot technology for everyone and much more.

Read moreBurr production with the Aries NGP Production Scara

As diverse the burr tool geometries are, equally diverse are the possibilities in the grinding software Qg1. For applications in the manufacturing, medical or dental sector, the geometries are available with the touch of a button. Aside from the software solution, SCHNEEBERGER offers the complete hardware contingent in the form of the 5 axes CNC Grinding Machine, chucking system and the fastest automation.

Read moreEnhanced grinding performance with the new Vasca NGV filtration system

4-stage filtration, massive 175 L/min at 12 bar, precisely regulated temperature control and for the first time with integrated dual-circuit drive cooling. The newly developed Vasca NGV make a significant contribution to the thermal stability of grinding machines.

Read moreProfiling of Broaching Tools, complete process in one single clamping with the Corvus NGB-BBA

SCHNEEBERGER Corvus NGB-BBA 6-Axes CNC-Grinding Machine: The ideal solution for grinding of internal or external broaching tools, as well as sharpening or profiling of such. New with the 3D model-based CAD/CAM grinding software Qg1.

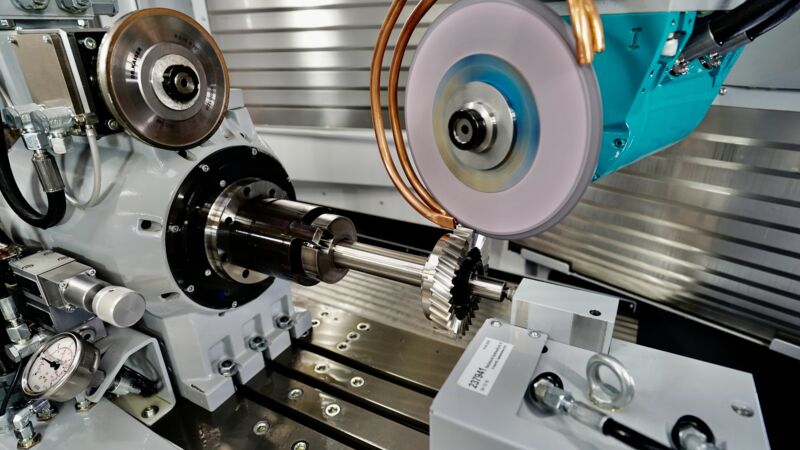

Read moreGear Milling Cutter production, logarithmical back relieve grinding

The universal 5-axis tool grinding machine Gemini NGM Linear produces, in addition to high-performance round tools, gear milling cutters with the highest accuracy requirements in carbide or HSS.

Read moreProfiling of Power Skiving Cutter in seven steps

The right grinding strategy is key for skiving cutter profiling. The SCHNEEBERGER application experts provide an initial insight using the example of a power skiving cutter, HSS, Ø 108.5 mm, L 19 mm, Z35.

Read moreThread Roll production in one chucking: SCHNEEBERGER has the right twist.

Thread-, ball screw- or gear rolling dies, the Gemini NGM linear masters all challenges. The optional wheel loader allows for cylindrical grinding, profiling, run-in and run-out taper as well as chamfering processes all in one chucking.

Read moreProfiling of Power Skiving Cutter on SCHNEEBERGER Gemini NGM Linear

Production of Power Skiving Cutter by single index generation grinding with form wheel; SCHNEEBERGER's customized complete solution for your production!

Read more