SCHNEEBERGER NEWS

The latest trends from the world of 5-axis CNC grinding

New features of the CAD/CAM software Qg1, further machine development, customer reports and background information. All of that, only in SCHNEEBERGER NEWS.

Enhanced grinding performance with the new Vasca NGV filtration system

4-stage filtration, massive 175 L/min at 12 bar, precisely regulated temperature control and for the first time with integrated dual-circuit drive cooling. The newly developed Vasca NGV make a significant contribution to the thermal stability of grinding machines.

Read moreProfiling of Broaching Tools, complete process in one single clamping with the Corvus NGB-BBA

SCHNEEBERGER Corvus NGB-BBA 6-Axes CNC-Grinding Machine: The ideal solution for grinding of internal or external broaching tools, as well as sharpening or profiling of such. New with the 3D model-based CAD/CAM grinding software Qg1.

Read moreBrighetti Meccanica – Manufacturer of high-precision broaches and a pioneer in digitalized production planning

Near Bologna Italy, BRIGHETTI MECCANICA manufactures broaches, for multi edge-, profile and special flutes, and among others, broaching tools for Torx wrenches. For their fully automated production (using Industry 4.0) they rely on SCHNEEBERGER technology.

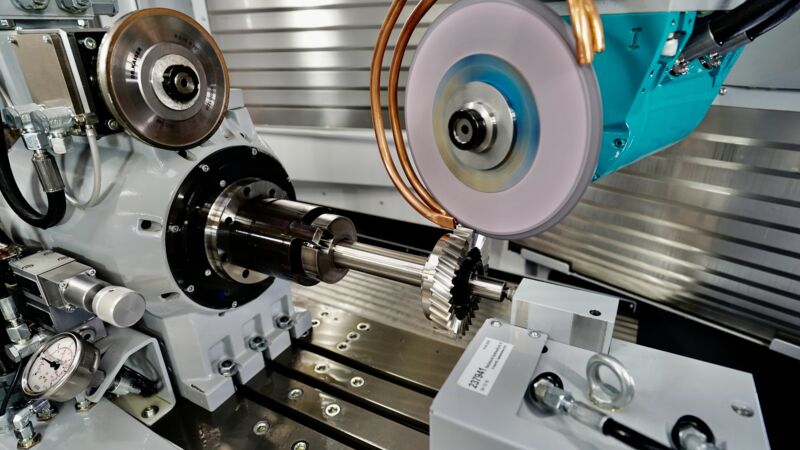

Read moreGear Milling Cutter production, logarithmical back relieve grinding

The universal 5-axis tool grinding machine Gemini NGM Linear produces, in addition to high-performance round tools, gear milling cutters with the highest accuracy requirements in carbide or HSS.

Read moreCIMT Beijing 2021

SCHNEEBERGER is back to exhibitions and back to real customer contact at the 17th China International Machine Tool Show in Beijing.

Read moreProfiling of Power Skiving Cutter in seven steps

The right grinding strategy is key for skiving cutter profiling. The SCHNEEBERGER application experts provide an initial insight using the example of a power skiving cutter, HSS, Ø 108.5 mm, L 19 mm, Z35.

Read moreProduction of globoidal cams on Norma NGC

Zhucheng Zhengxin Machinery has been producing index drives since 2008. The quality and precision of the globoidal cams soon reached its highest level after CNC technology in grinding machines was introduced. Manual polishing was no longer necessary and sales figures soared nationwide.

Read moreStep drill production and regrinding with Qg1

The expanded step drill program in the SCHNEEBERGER Qg1 grinding software now offers even more geometries and functions.

Read moreKristen + Görmann, tools systems made in Renchen

SCHNEEBERGER grinding machines are the obvious choice wherever there is a need for a fast and flexible response to individual customer demands and ultimately to the most varied and complex production requirements.

Read moreThread Roll production in one chucking: SCHNEEBERGER has the right twist.

Thread-, ball screw- or gear rolling dies, the Gemini NGM linear masters all challenges. The optional wheel loader allows for cylindrical grinding, profiling, run-in and run-out taper as well as chamfering processes all in one chucking.

Read moreProfiling of Power Skiving Cutter on SCHNEEBERGER Gemini NGM Linear

Production of Power Skiving Cutter by single index generation grinding with form wheel; SCHNEEBERGER's customized complete solution for your production!

Read moreSIG-TECHNIK sharpens hobs with SCHNEEBERGER Technology

SIG-TECHNIK Werkzeug GmbH in Grebenstein looks back on over 30 years of experience in the field of cutting tools. Through continuous development of machine technology and grinding processes, SIG has been able to establish a leading reputation in the manufacturing of form tools. A second important pillar of the company is the reconditioning of gear cutting tools, such as hobs as well as standard cutting tools, step drills and milling cutters.

Read more